Industrial separation exploits magnetism

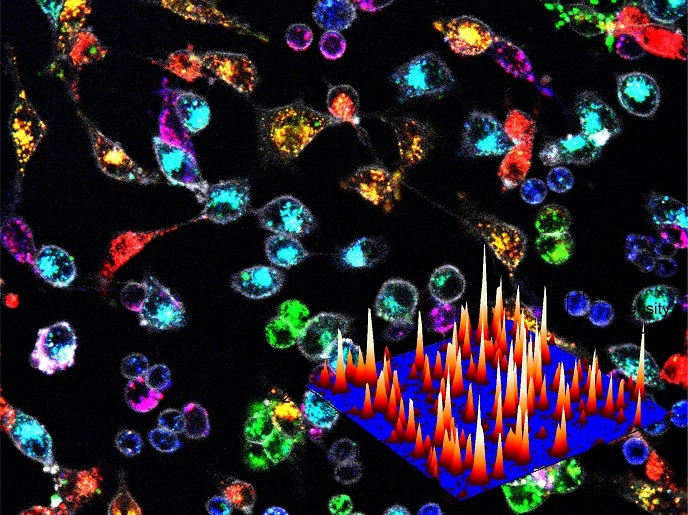

Biotechnological production techniques find myriad applications in industrial, food and pharmaceutical sectors. Properties can be carefully controlled with responsible manufacturing to yield biocompatible and sustainable materials and methods. Currently, processes to separate the target products from a complex mixture make up nearly 80 % of production costs. Thus, better separation technology could significantly increase profits and the EU’s competitive global position. Scientists initiated the EU-funded 'Advanced magnetic nanoparticles deliver smart processes and products for life' (MAGPRO²LIFE) project to drastically reduce costs using magnetic separation and extraction techniques. They developed pilot production lines for bio, food and pharmaceutical applications. They optimised technology developed in the Sixth Framework Programme (FP6) project 'Magnetic Field Assisted Biomaterials Processing' (NANOBIOMAG) for this purpose. The new technology platform integrates cost-effective, industrial-scale manufacture of functionalised, super-paramagnetic nanoparticles and similarly large-scale process technology to separate the particles from the production stream. Novel methods to produce the magnetic nanoparticles and functionalise them were developed as were new equipment and analytical methods. A magnetic centrifuge and some of those methods are close to commercialisation. Researchers successfully demonstrated the technology’s manufacturing and economic benefits through use with real industrial product streams. Further, the materials and processes adhere to strict standards of health and safety that completely fulfil all requirements of food, bio and pharma applications. Industrial partners are ready to take the technology to market. Genetic technology makes a number of sophisticated pharmaceuticals possible but costs are quite high and impose significant economic burdens on healthcare systems. MAGPRO²LIFE has provided an alternative with high-value proteins derived from natural and recombinant sources. Commercialisation of equipment, processes and products will benefit the pharmaceutical, food, chemical and technical industries.

Keywords

Protein, pharmaceutical, food, functionalised magnetic particles, biotechnology, separation, extraction, pilot, nanoparticle, centrifuge, recombinant