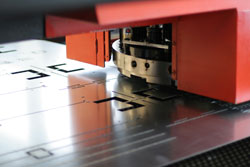

Introducing noiseless tool design

One of the environmental hazards of the modern mechanical machinery industry is the high levels of noise it generates. Particularly, machine tools such as punching machines produce excessive noise leading to potential physical and physiological harm to workers in the long term. Although provision was taken to reduce noise levels within closed industrial surroundings, little effort was made to consider this aspect in the design process of machines. Addressing this issue, the NOISELESS project focused on designing more 'quiet' machine tools by taking effective noise control measures while improving wear and tool life. Part of the project work involved the development of a new method that allows identification of tool wear and its correlation with noise. The method can be employed in punching tools and offers wear analysis with the aid of optical and con-focal techniques. The derived tool profiles displayed different level of wear, which can then undergo further inter-comparison. The method can find useful applications in tool manufacture for analysis of correlation between noise and wear. Its adoption can improve the design procedures' efficiency and reduce excessive experimentation, which is costly. Moreover, through optimised design the tool life can be extended, while noise generation and transmission to the environment are considerably limited.