Upskilling shipyards with robotics and digitalisation

Europe’s shipbuilding industry is crucial to its economy and global trade. The sector supports over 120 000 jobs – both direct and indirect – with small and medium-sized shipyards bolstering local economies, especially in coastal areas. These jobs include steel production, electronics and ship repair. “European shipyards excel at building advanced vessels that fetch high prices worldwide,” says Mari4_YARD project manager Ana Rodríguez Vidal from AIMEN in Spain. “Strategically, the sector bolsters national defence and maritime infrastructure, ensuring connectivity and security across Europe.” However, challenges loom. Asian competitors dominate mass production, leveraging economies of scale to cut costs, while Europe focuses on customised, high-tech vessels. “Stricter environmental rules demand ongoing research, and rising material and labour costs are adding to the pressure,” adds Vidal.

Boosting shipyard manufacturing efficiency

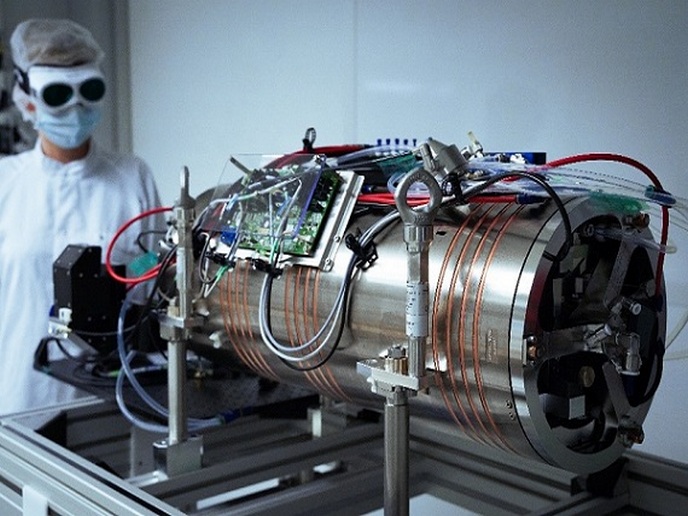

The primary objective of Mari4_YARD was to address these challenges by boosting manufacturing efficiency in small and medium-sized shipyards, while retaining industry-specific worker knowledge. To achieve this, the project set out to develop and implement a range of human-centric solutions in the naval sector. These solutions included digitalisation and high-payload collaborative robots for assisting operators. Other solutions included head-mounted displays for training, projectors and handheld devices to provide instructions to operators, and upper-limb and lumbar exoskeletons to support heavy lifting. “Beyond this technology, the Mari4_YARD project also aimed to strengthen EU shipbuilding by designing various training courses,” notes Vidal. The project took a two-step approach to implementation. For the technology, scenarios were developed and tested, from the lab scale to final validation and deployment at two small and medium-sized shipyards. A barrier-driven approach was also taken to identify market gaps that might hinder the adoption of these Mari4_YARD technologies. This involved gathering feedback during testing and training, and introducing the project’s technologies to industry stakeholders and workers.

Assessing market potential, filing patents

The results of this work were shared with stakeholders and end users during workshops. The goal of this was to ensure optimal potential uptake of the technologies in the future. Two patents for exoskeletons were filed, and several other technologies have been assessed for their market potential. “Several use cases and technological solutions were evaluated, with 12 selected for demonstration at small and medium shipyards,” says Vidal. “These demonstrations delivered impressive results in terms of productivity, efficiency, accuracy and quality, alongside savings in time, cost and resources, and high user satisfaction.” Didactic Factories – general-purpose showrooms – will stay open past project completion to help train and upskill workers on the developed tools, while offering infrastructure for start-ups and small companies to test new solutions in a quasi-industrial setting.

Enhanced work conditions, improved safety and productivity

The project team hopes that the eventual commercialisation of these tools developed will assist workers in small and medium shipyards by enhancing daily work conditions, improving safety and ergonomics, and boosting productivity. “Shipbuilding SMEs can not only leverage Mari4_YARD tools but also access our training courses and publications to enhance their operations,” explains Vidal. “Adopting advanced robotics and digital solutions can strengthen the sector’s competitiveness and attract and engage younger generations of workers.” The project team also hopes that the Mari4_YARD project can serve as a benchmark, paving the way for standardisation in automation at small and medium shipyards.

Keywords

Mari4_YARD, robotics, digital, shipyards, coastal, shipbuilding, electronics