Laser-based technology platform speeds up functional surface development

Bio-inspired surface structures offer major commercial potential for designing functionalised surfaces that meet the requirements of industrial markets. Surfaces with controlled topographic characteristics can result in products with special functionalities, such as antibacterial, self-cleaning properties, friction reduction and optical security functions. Currently, there is a need to mass produce them at low cost. Developing high-power ultrashort laser sources will satisfy this increasing need for economical products with novel surface performance.

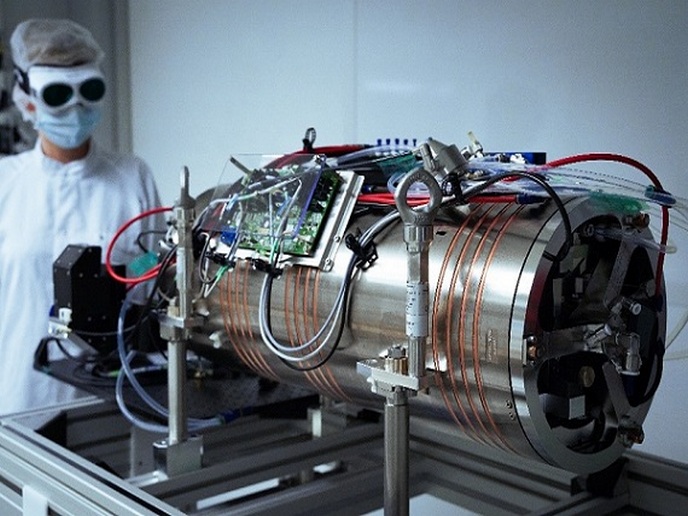

High throughput

Scientists supported by the EU-funded LAMPAS project have reached the target parameters of a kilowatt-class ultrafast laser system. The developed pulsed laser surpassed 1.5 kW of average optical power and operated at gigawatt-class peak power in test trials. It exhibited fundamental mode beam quality at a near-infrared wavelength of 1 μm. In addition, they will integrate a demonstrator system into a machine intended for industrial laser micromachining of larger square-metre-size surfaces. The laser was showcased at the Advanced Solid State Lasers Conference in October 2021 by project participant TRUMPF, an industrial machine manufacturing company. Based in in Germany, it is one of the world’s largest providers of machine tools. According to a news item posted on the ‘Photonics Media’ website, “the system operated at an average power of 300 W, followed by thin-disk laser booster stage providing more than fivefold amplification.” “The compact and efficient thin-disk multipass amplifier module is a technological breakthrough in terms of robustness,” explained the new release. “The disk’s large area allows extreme peak power to be generated without the need for temporal post-compression of the pulses, which are adjustable in duration between 3 and 10 ps via the front-end. A narrow spectral bandwidth below 1 nm is ideal for direct laser interference patterning. The linear amplifier chain enables high flexibility, including burst functionality as well as the full 1.5-kW average power over a wide range of repetition rates between 375 kHz and 5 MHz, compatible with fast scanners.”

Low-cost production

The laser’s improved level of productivity should considerably reduce the processing cost per part. This will make new applications financially feasible. It will also ramp up the production of functionalised surfaces for applications. These include household appliances, pharmaceutical packaging, industrial machinery, medical implants and tools, food processing, sports equipment, furniture finishes and energy storage. LAMPAS (High throughput Laser structuring with Multiscale Periodic feature sizes for Advanced Surface Functionalities) aims to boost the potential for laser structuring for the design of recently functionalised surfaces, thus enhancing the efficiency, flexibility and productivity of the process. This will provide anti-fingerprint, antibacterial, anti-friction, and anti-fouling properties as well as decorative finishes, easy-to-clean surfaces, anti-counterfeit marking and anti-icing features. Ultimately, the project should provide the European industry with a cost-efficient and robust technology to manufacture a broad variety of functional surfaces. It ends in June 2022. For more information, please see: LAMPAS project website

Keywords

LAMPAS, laser, surface, functional surface, amplifier