Next-generation PEF technology promises safer and healthier food at a lower cost

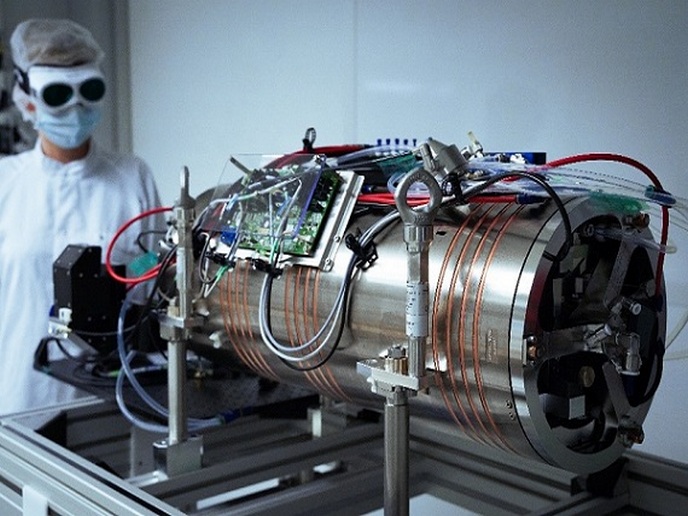

The FieldFOOD (Integration of PEF in food processing for improving food quality, safety and competitiveness) project finds its roots in what we could call a paradox. On the one hand, PEF is extremely appealing: it can prevent the negative impact of heating associated with other food processing technologies, reduces energy needs and water consumption, and provides safer, healthier food with a longer shelf life. But on the other hand, there are still obstacles to its widespread adoption. Apart from its use in potato processing and for the pasteurisation of fruit juices and smoothies, the technology has not yet met with the success it was promised. “The starting point of our proposal was to conduct a survey involving all project partners, to identify the bottlenecks that prevented the introduction of the technology. These included the fact that PEF processing was intended to supersede instead of complement existing food processing technologies, the lack of a systematic approach to its integration, industrial systems lagging behind end-user requirements, and high costs associated with existing PEF generators,” explains Prof. Javier Raso, coordinator of FieldFOOD on behalf of the University of Zaragoza. To overcome these problems, Prof. Raso and his team conducted a systematic process analysis of applications such as fruit juice processing, tomato product processing, winemaking, olive oil extraction and cider production. They identified the specific requirements of all these sectors, designed modular, portable and low-cost pulse generators and modified processing steps and parameters to successfully introduce these generators in the processing line. “Our technology is miles apart from its costly, bulky and heavy counterparts. It is portable, allows for the process to be quickly adapted depending on the product being treated, and is small enough to be integrated in existing production lines without the need for major renovations,” says Prof. Raso. “It even allows for a rental system, thereby avoiding the need for large capital investments that some companies, particularly SMEs, would find difficult to commit to.” In the case of winemaking, PEF treatment with FieldFOOD technology was found to halve maceration time and result in a fruitier wine. The energy required for the physical peeling stage was reduced by 20 % and, in the case of oil and fruit juices, extraction was improved by up to 5 %. The technology was successfully demonstrated at a pilot plant, a demonstration which also helped the consortium in identifying room for improvement towards easier market introduction. “We are also following up on our research into suitable know-how generated in FieldFOOD, to evaluate the industrial feasibility of the application of PEF not only to other applications in the food industry, but also for other sectors such as pharmaceutical or biotechnological industries,” Prof. Raso concludes.

Keywords

FieldFood, Pulsed electric field, PEF, food decontamination, food processing