Chromium and carbon nanodispersion coating

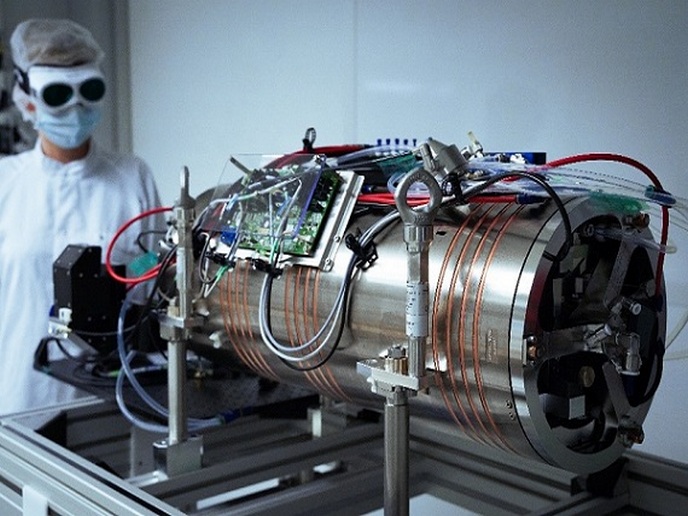

Vehicles are a significant contributor to emissions of particulate matter, not only from their exhaust pipes but also from engine and tyre wear. Europe is tightening its emissions' standards and auto manufacturers will require new technology to comply. Participants in the NANOCOAT project, funded in part by the GROWTH Programme, investigated the potential of new coatings to improve engine component performance characteristics. The Fraunhofer Institute for Material and Beam Technology in Germany, experts in tribological applications, led the development of a chromium and carbon nanodispersion (Cr+C-ND) coating. They combined physical vapour deposition (PVD) with vacuum-arc discharge to deposit extremely thin layers of the coating. Laboratory tests indicated increased hardness, crack resistance and oxidation resistance in comparison to a typical carbon film. The lower friction coefficient of the Cr+C-ND coating is also an advantage for tribological applications, particularly in dry or mixed lubrication conditions. The Cr+C-ND coating can easily be applied to metal substrates with complex geometry such engine components. Faster rates of deposition are also possible with the use of pulsed arc technology. Further to the positive NANOCOAT results, the Fraunhofer Institute for Material and Beam Technology had sought patent protection for the new coating.