Coated components with less friction and wear

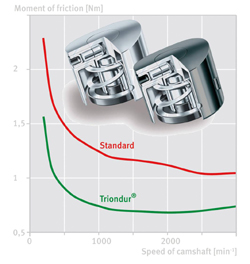

Coated components are very frequently used in tribological systems in which surfaces of two parts are in moving contact with one another as is the case in the automotive industry. Coatings allow for wear reduction and at times, lighter materials providing technical solutions for conforming to emerging emission laws. Nanostructured coatings are composed of nanometre sized grains and are known for their capacity for the unlikely combination of toughness and hardness while also being lightweight. The NANOCOAT project has developed new nanostructured coatings for challenging and extensive mechanical applications such as gears as well as for car engine components such as cylinders and tappets. More specifically, Cr (chromium) based coatings and carbon based coatings were created. Compared to steel surfaces, these coatings exhibited significantly better tribological behaviour in both dry and lubricated contact with steel. A valve train test was conducted indicating that the target friction reduction of 10% was surpassed since 24% friction reduction was achieved. Furthermore the life span of the tribological system was increased as much as 350 times merely by applying the coating on one part of the tribological system.