Production scale-up drives nanomedicines to market

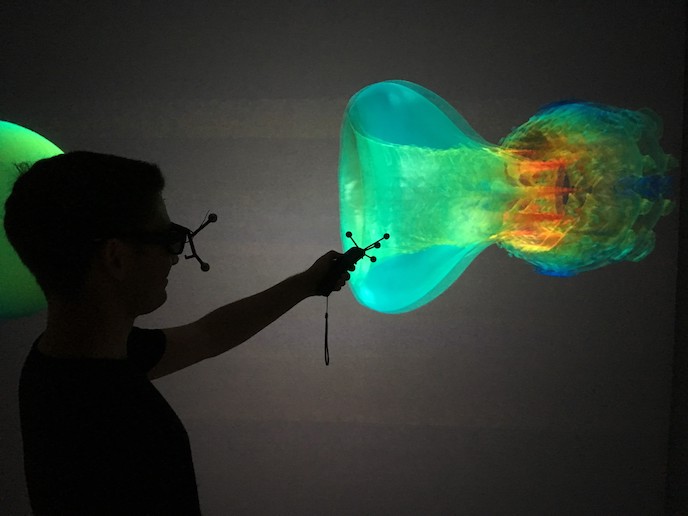

After nearly four years of work, the NanoPilot (A Pilot Plant for the Production of Polymer based Nanopharmaceuticals in Compliance with GMP) project pilot plant in Spain is up and running, and the team is now working on the process to certify the plant. Three nanopharmaceuticals were developed and are now closer to the point where they can be tested on patients. “One of the barriers to innovative European nanomedicines reaching the market has been the lack of specialised plants such as this,” explains NanoPilot project coordinator Iraida Loinaz from CIDETEC in San Sebastián, Spain. “Our aim in this project has been to address this need and establish good practice. We have also advanced in the development of quality control protocols that have been validated for the characterisation of nanopharmaceuticals.” Maximising opportunities The four-year project was launched in January 2015 to establish a nanopharmaceuticals plant operating under good manufacturing practices (GMP), the quality system required in the manufacturing of drugs. GMP is compulsory in the manufacturing of pharmaceuticals for use in patients, even if the drugs are under development and intended to undergo clinical testing. Nanopharmaceuticals provide drug developers with a range of potential advantages. Due to their incredibly small size, nanoparticles can be absorbed more easily and targeted at specific organs or tissue areas. Active agents such as proteins and nucleic acids can be reformulated – or ‘nanoformulated’ – for accurate delivery to these specific targets. The toxicity of some existing therapies can therefore be reduced, their efficacy improved, and the overall patient experience transformed. While there is little doubt that nanopharmaceuticals present the pharma and medical sectors with huge potential, getting the technology to market is a key challenge. Producing innovative nanopharmaceuticals in the quantity and quality required for clinical trials is incredibly expensive and often beyond the means of Europe’s innovative SMEs. “The inability to upscale the nanopharmaceutical manufacturing limits the capacity of SMEs to advance their research and slows the development of innovative drugs,” says Loinaz. “This is why we urgently need to provide these organisations with the tools to help them validate their technologies.” Open innovation The three nanopharmaceuticals trialled at the plant were a short interfering RNA for the treatment of dry eye syndrome, a possible HIV vaccine, and nanoparticles for the treatment of interstitial cystitis / painful bladder syndrome. The aim now is to open the plant up to other types of projects, not only to nanomedicines ready to enter initial clinical trial phases, but also to drugs ready for late clinical phases and even commercialisation. The plant facilities can also be used to produce other innovative therapies and products that require intravenous administration, as well as smaller batch sizes. “We are working hard to ensure that this plant is fully sustainable and are currently working on a business plan that exploits the potential of the plant as much as possible,” says Loinaz. “We really think that we have the capabilities here to go much further. We have already been in contact with several technology developers, and we are excited that new projects will begin here in the near future.” Loinaz adds that successful collaboration between the consortium partners was essential, and made possible thanks to the NanoPilot project. “This allowed us to explore highly innovative nanoformulations and innovative production processes, something that would have been very difficult to do otherwise.”

Keywords

NanoPilot, nanoformulations, drug, pharmaceutical, clinical, HIV, nanoparticles, nanomedicines