Nano-enhanced industrial materials: Building the next European industrial revolution

The global market for nanomaterials (materials which often have specific properties due to their small particle size) is estimated at around 11 million tonnes with a market value of EUR 20 billion and growing. The current direct employment in the nanomaterial sector is estimated at between 300 000 and 400 000 in Europe. Whilst most of the nanomaterial sector is still dominated by materials in use for decades, such as carbon black (used for tyres) or synthetic amorphous silica (used in applications including tyres, toothpaste and food powders), researchers have been in the process of developing many new nanomaterial-related applications, many now ready for commercial use.

Overcoming barriers to successfully address societal challenges

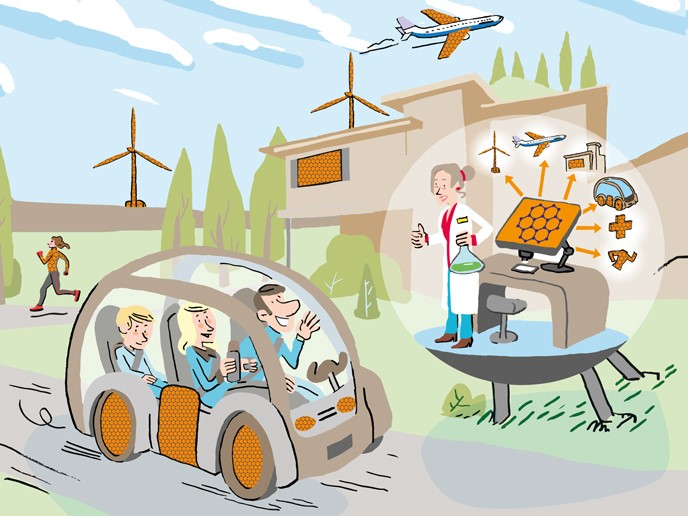

Europe has been at the forefront of this research, and funding through the Horizon 2020 programme aims to bridge the gap between nanomaterial research in the lab and getting innovative technologies onto the market. This is crucial, as nanomaterials look set to help overcome several pressing and urgent societal challenges. These include the need to care for an increasingly ageing population, reducing carbon emissions and fighting climate change, the more efficient use of finite resources and the development of more sustainable methods of transport. But there are still barriers to overcome before European industry can take full advantage of the large-scale commercialisation of innovative, safe and sustainable nanomaterials. The main challenge is to develop seamless integration of materials and processing technologies for using nanomaterials in industrial production. Other challenges include: improving the control and monitoring of the conditions required for the use of nanomaterials in industrial processes; increasing the levels of robustness and repeatability of these processes; and optimising and evaluating the performance and functionality of the production line and the resulting products.

A focus on the projects

In this CORDIS Results Pack, we focus on 14 projects that have made clear and distinguished progress towards overcoming these barriers and demonstrating how nano-enhanced advanced materials can be safely, sustainably and competitively launched into the industrial mainstream. One group of featured projects, including the NANOTUN3D and FAST projects, has showcased how nanomaterials can positively contribute to the growing revolution in 3D printing which will be keenly felt in the medical, automotive, space and construction sectors. Several showcased projects are contributing to lead the emerging field of nanomedicine in new and exciting directions. The PEPTICAPS project has pioneered nano-capsules as carriers of medicine able to treat common conditions, such as allergic and irritant dermatitis and sunburn, whilst the NanoPilot project has constructed a pilot plant to produce small batches of polymer-based nanopharmaceuticals. Meanwhile, the NANOFACTURING project has finalised a manufacturing platform for solid core nanopharmaceuticals, including new manufacturing processes and better supply chain coordination for medium- to large-scale production, all with the aim of bringing more targeted and effective nano-based treatments to market. Finally, many of the selected projects have been engaged in scale-up activities that will embed enhanced nanomaterials into a range of traditional industrial sectors. For example, the ProDIA project has successfully demonstrated the feasibility of large volume industrial production processes for hybrid nanoporous materials as finished products, whilst the IZADI-NANO2INDUSTRY project has demonstrated how nanotechnology can improve conventional materials and the manufacturing processes of injection moulding, casting and coating. Finally, the NANOLEAP project has enabled manufacturing SMEs, primarily in the construction sector, to scale-up their nanocomposite production processes, address processing bottlenecks and seek expert advice.