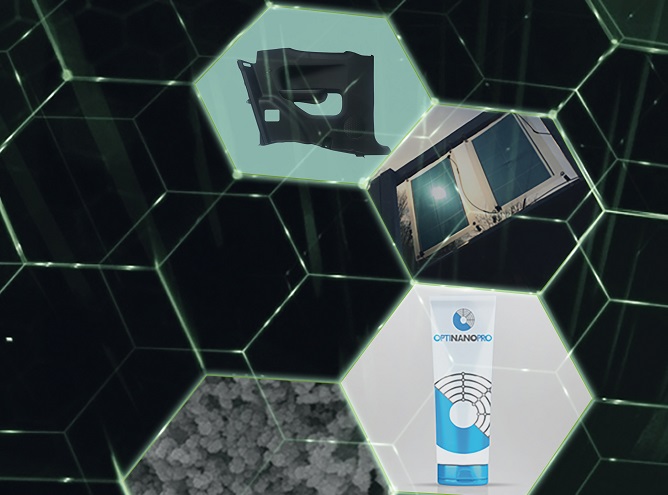

Integrating nanomaterials into existing production lines

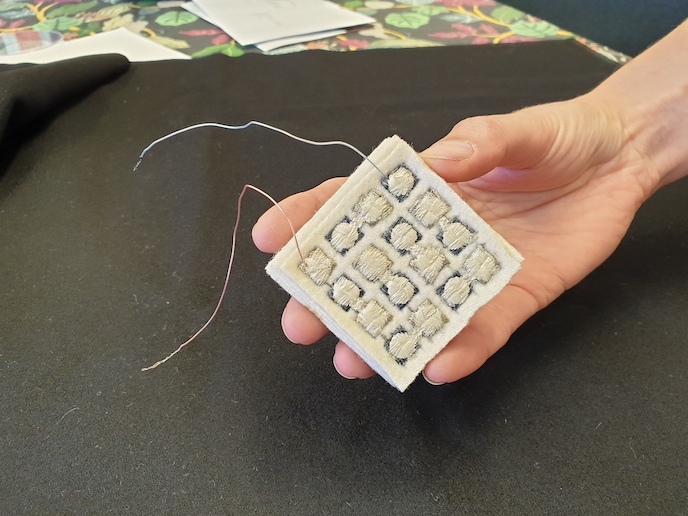

With a focus on the packaging, automotive and solar sectors, the OptiNanoPro (Processing and control of novel nanomaterials in packaging, automotive and solar panel processing lines) project brought together 15 partners from across the supply and value chains. Together, they successfully demonstrated the integration of nanomaterials into existing production lines, considering performance improvements, along with such issues as nano-safety, sustainability, productivity and cost-effectiveness. Researchers started by developing innovative polymer nanocomposite formulations combining the appropriate polymer and nanoparticle types and contents for each applicative requirement. In nanotechnology, polymer nanocomposites are defined as solids consisting of a mixture of two or more phase-separated materials. Next, they adjusted different polymer converting processes for the nanocomposites’ bulk and/or surface applications in semi-industrial production lines. These processes, typically used within the targeted packaging, automotive and OPV industries, included: high-energy ball milling (HEBM), compounding, injection moulding, electrospray deposition, coating and lamination. 25 exploitable processes and products The result of this work was the creation of 25 key exploitable processes and products, including barrier-laminated and injected packages (tubes, pouches and jars). These packages use both bio and standard plastics to cut oxygen permeation in half, thus offering significantly improved protection to food products and cosmetics. The project also produced a self-cleaning OPV laminate with the potential for increasing a solar panel’s ability to harvest energy. In the automotive field, OptiNanoPro researchers developed parts that weigh up to 20 % less than current parts – a weight reduction that will substantially reduce fuel consumption and CO2 emissions. A life cycle assessment (LCA) was conducted to measure each product’s environmental impact, starting from resource extraction and on through to production, use and end-of-life. “Designing new products with versatile and valuable life cycles can help keep them from ending up in landfills or littering our oceans,” explains OptiNanoPro project coordinator Elodie Bugnicourt. “We also created a number of easy-emptying tubes and pouches that help achieve a 50 % decrease in residual product when discarding the package after use.” An eye towards marketisation According to Bugnicourt, marketisation and business plans are now available for the most advanced results. “These products will be further explored, leading to the selected innovations being marketed either via a sub-group of partners acting together along a supply or value chain, or via partners acting on their own in terms of single results used in new applications outside of the consortium,” she explains. “It is also very likely that we will spin off further research ideas along the lines opened in the project, for example in the transfer of the project processes and material innovations towards new sectors.”

Keywords

OptiNanoPro, nanotechnology, nanocomposites, packaging, automotive, solar, polymer