Self-cleaning, water-resistant plastics for cars

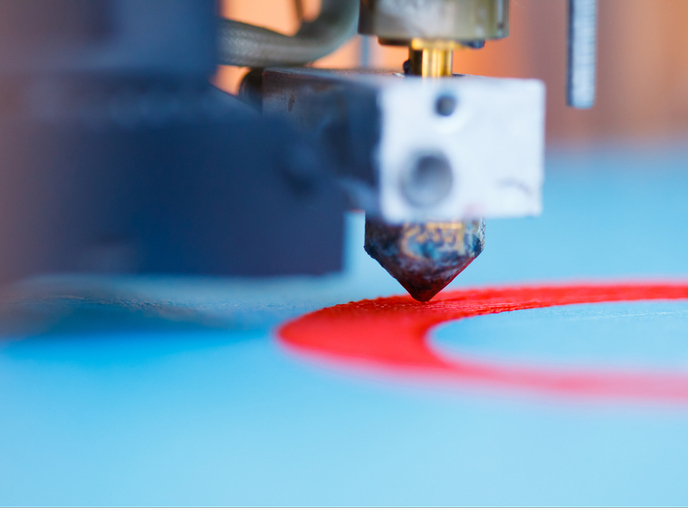

The most famous natural example of self-cleaning can be found on the leaf of the lotus flower. Researchers have attributed this feature to highly water-resistant nanostructures known as micropillars, Water resistance and self-cleaning are desirable features for plastics, so scientists have begun exploring ways to synthetically engineer nanostructures that would enable these features. A project called NANOCLEAN was funded by the EU to optimise and upscale the technologies needed to produce nano-structured self-cleaning plastics for use in cars. This research has enabled the establishment of several small companies that are carrying the research forward to commercialisation. Specifically, the project tested technologies such as laser pulsing, and industrial injection moulding on nano-structured surface moulds to produce a self-cleaning, hydrophobic plastic based on the lotus structures. Several specially formulated and modified polymers were also developed and tested for hydrophobicity. One main conclusion of the research is that micro- and nanotextures can be applied to three-dimensional (3D) curved surfaces and that these textures are durable. NANOCLEAN technology prototypes showed wettability and easy-to-clean properties, as well as optical effects that could be used for other applications. Overall, the project demonstrated that injection moulding represents a promising technology to develop a nano/micro-structured surface with high performances and potentially low costs. The NANOCLEAN approach should provide solutions in passenger and industrial vehicles, and could have other applications in areas like biomedicine, electronics and white appliances.