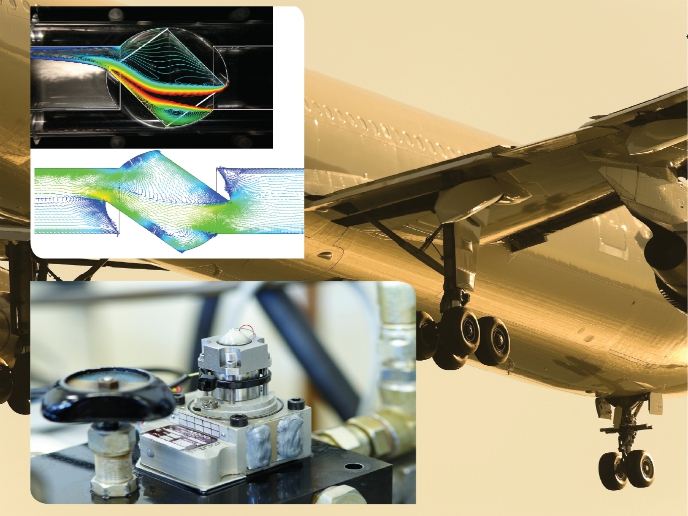

Multi-chip electronics platform eliminates aircraft hydraulics

All-electric aeroplanes will exhibit significant decreases in complexity, weight and fuel consumption. The latter has important implications for operating costs and environmental impact. In addition, electrical systems are expected to lead to significantly reduced maintenance costs compared to hydraulic systems. EU-funded scientists working on the project CREAM focused on eliminating as many hydraulic power sources and hydraulic lines as possible through the development of high-performance electromechanical actuators (EMAs). Conventional aircraft use actuators powered by hydraulic circuits containing pressurised fluids to move various aircraft control surfaces such as wing flaps and landing gear. EMAs use electric motors to produce a torque that drives the actuation for a much simpler and more compact solution. The CREAM multi-chip power module (MCPM) is an electronics platform packaging the various chips or functionalities on the same substrate for use as a single component. It includes both the power electronics components and the control electronics integrated in the actuator housing. The system delivers high-power density in about half the volume and mass. With advanced thermal management, the electronics will withstand the extreme operating conditions associated with air transport. Four fully assembled MCPMs incorporating all sub-parts of the EMA were manufactured and tested in a harsh-environment testbed. CREAM results establish the ability of EMAs to reliably actuate flight-critical control surfaces on aircraft. Facing intense competition from the United States, the EU is now in a position to build on project outcomes and assume a leadership role in the challenging aeronautics sector.