Novel noise reduction concepts for aircraft

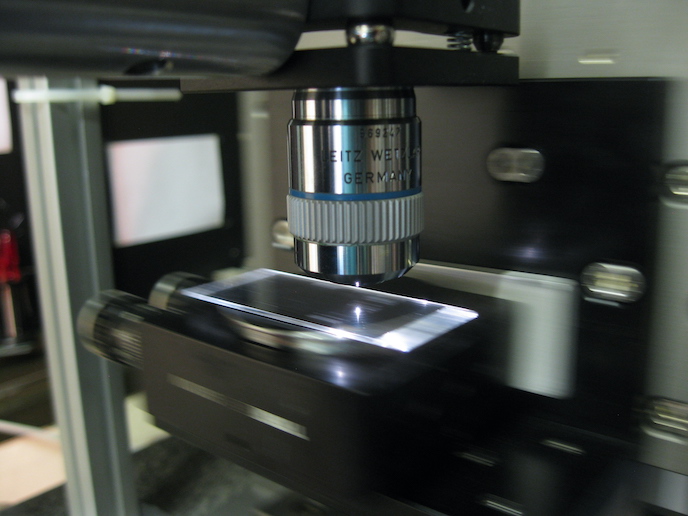

The exhaust gas of a gas turbine jet engine is used for propulsion. In order to achieve adequate thrust, the exhaust gases are accelerated through a propelling nozzle. Radiation of turbomachinery noise (created by the engine turbine and fan) through bypass and core nozzles is an important source of noise on modern aircraft yet it has been largely overlooked. European researchers focused on this issue with EU-funding of the ‘Turbomachinery noise radiation through the engine exhaust’ (Turnex) project. The consortium focused on experimental methods and numerical modelling to enable prediction of fan and turbine noise radiation. Enhanced understanding of the physics of noise generation related to specific component geometries, engine specifications and airflows would facilitate reliable evaluation of noise reduction concepts. Turnex scientists experimentally tested model-scale geometries of conventional engine exhaust systems. They also studied innovative noise reduction concepts, including novel nozzle configurations. Together, data formed a solid framework for validation of models. The consortium made significant advances in numerical modelling and conducted a parametric study of geometry- and flow-parameter effects on a full-scale engine configuration. Finally, using models and validation data, the consortium evaluated various methods of estimating noise levels. Results should benefit European fan-noise test facilities. Knowledge generated by the Turnex consortium should be particularly important to aerospace manufacturers, helping them to design quieter systems for less noise pollution. In addition, less noise pollution by airplanes, particularly during take-off and landing, could help win public approval for the building of future airports, providing a boost to numerous jobs related to air travel.