Laser innovation lights up electronic display sector

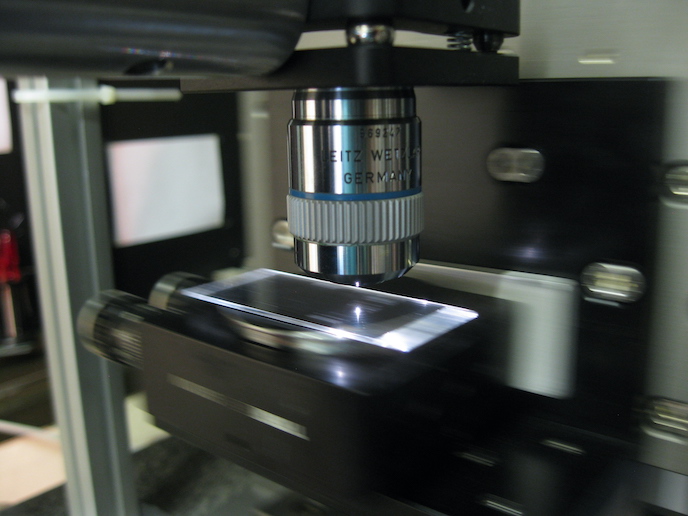

Femtosecond lasers emit extremely short pulses, in the order of a millionth of a billionth of a second. One of their most important applications is in micromachining, the fabrication of structures on the micrometre scale. “The extremely short duration of the pulse, together with the corresponding high peak intensity, allows for the clean and precise modification of materials,” explains DISPLAYGHT project coordinator Roberto Osellame from the National Research Council (CNR) in Italy. Another interesting factor is their capability to modify – in 3D – transparent materials such as glass or crystal. Femtosecond lasers can be used in this instance to write photonic circuits, i.e. micrometric channels where light remains confined and routed inside the glass. These circuits can be used in liquid crystal displays (LCDs) found in TV screens and other electronic displays. This of course is far from straightforward. “One has to consider that a typical display might have millions of pixels, where light needs to be distributed as evenly as possible,” says Osellame. “This represents a great challenge. Complex photonic circuits need to be written with exquisite control.”

3D circuit design

Osellame met Jonas Zeuner and Chiara Greganti, co-founders of the start-up VitreaLab during a quantum technology research project. As PhD students, the pair noted that current display technologies direct just 5 % of generated light power toward the viewer. Their solution was to use photonic circuits to route all light to the right points – the pixels – and thus avoid any waste of power. “My technology, based on femtosecond laser micromachining, seemed the perfect match,” notes Osellame. “This was the start of the DISPLAYGHT project.” DISPLAYGHT focused on demonstrating the feasibility of these highly complex circuit structures being fabricated, and this process being automated as much as possible, in order to achieve high throughput. These advances enabled the team to build complex photonic circuits capable of distributing red, green and blue laser light to the pixels in a display. This light is invisible as long as it stays in the photonic circuit. However, the 3D capability of the technology enables the circuit to be bent at the pixel site, directing the light out in the direction of the viewer. The project team was able to showcase a 27 000 sub-pixel prototype in all three colours, helping to address a key concern expressed by investors – how this technology can be scaled up. “These insights also allowed us to significantly increase our patent portfolio, another key element likely to attract investors,” adds Zeuner.

Tapping industry interest

The success of the project, funded by the European Research Council, has resulted in VitreaLab experiencing significant growth. The company now has an independent laboratory dedicated to several target applications, has raised significant amounts of funding, and has established strong links with potential customers. “There has been a lot of interest from industry,” says Zeuner. “At the outset of the project, the targeted application was the usage of the laser-fabricated glasses as backlights in LCDs. But during the project, a number of other applications were identified. These include 3D displays and augmented reality goggles.” Prototypes are currently being shipped to potential partners, and their feedback is helping to shape future priorities. Nevertheless, more work is needed before the technology can be commercialised. “In particular, the move towards multibeam laser fabrication, a key step for low-cost manufacturing, will require further development,” notes Osellame.

Keywords

DISPLAYGHT, lasers, micromachining, electronic, LCDs, pixels, photonic, circuits