Forests: a renewable resource for everyday materials

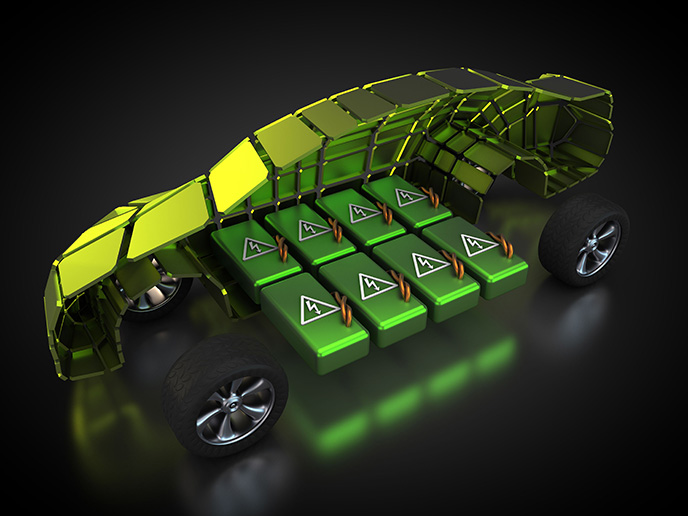

Forests and the by-products of wood and paper mills represent a wealth of renewable resources that can be used to generate everyday materials. Making and using these materials could reduce energy consumption, gas emissions and harmful waste disposal, and it could even lead to new employment opportunities. Forest resource sustainability through bio-based composite development' (Forbioplast) is an EU-funded project that has made huge strides towards developing such eco-friendly materials. The market potential of three of their products (fertilisers, tomato yarn and pots) is already being investigated. The research team used wood fibres enriched with minerals to create a coated fertiliser that could satisfy a growing demand in cereal and potato crops. They also created a tomato yarn that could replace over 100 000 tonnes of environmentally unfriendly string currently used in the EU. Tomatoes are the second most important vegetable crop in the world, but the yarn could also be used for cucumbers, grapes and tree grafting. The project has also produced bio-degradable pots which have all the properties of regular pots and are light and inexpensive. These pots can be used in horticulture, tree nurseries and to grow aquatic plants. Forbioplast researchers have investigated the use of polyurethane foams created from wood fibres and lignin for certain car parts. In addition, they have developed packaging for the cosmetic industry which is currently being tested for toxicity and how well it seals. The team found that treating wood fibres with enzymes prior to manufacture made the materials more biodegradable. The Forbioplast project has given a huge boost to the idea that cheaper, quality eco-friendly materials should be easily available. The fact that these materials are themselves biodegradable means that forests can be continuously recycled and could thus become a virtually inexhaustible resource.