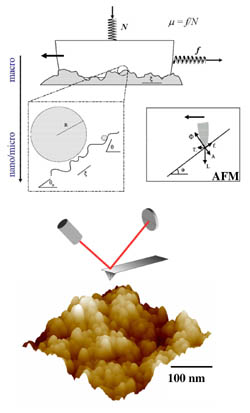

Studying corrugated samples at the sub-micron scale

Vacuum coatings result in reduced wear, and in some cases enable lighter materials to be used. These nanostructured coatings, which combine high hardness with high toughness, have contributed to the improved quality of automobile parts. The NANOCOAT project used an atomic force microscope (AFM) to study the properties of the coatings at the sub-micrometre scale. A protocol was written for characterising friction properties of corrugated surfaces, which comprise of alternating parallel ridges and grooves. They also represent the greatest challenge when measuring coatings. The first part of the protocol described how the AFM was used to simultaneously acquire the topographic and friction maps of surfaces. The topographic map was used to calculate the tilt of the sample's surface. The second part of the protocol concerned the application of the topographic correction to experimental data. Researchers noted that the friction behaviour of coatings was not uniform at the one micron scale. This may be as a result of the non-homogenous chemical composition of the coating at the sub-micron scale. A second possibility was that it could also be due to the presence of contaminants on the coating's surface.