Efficient solar cell energy production

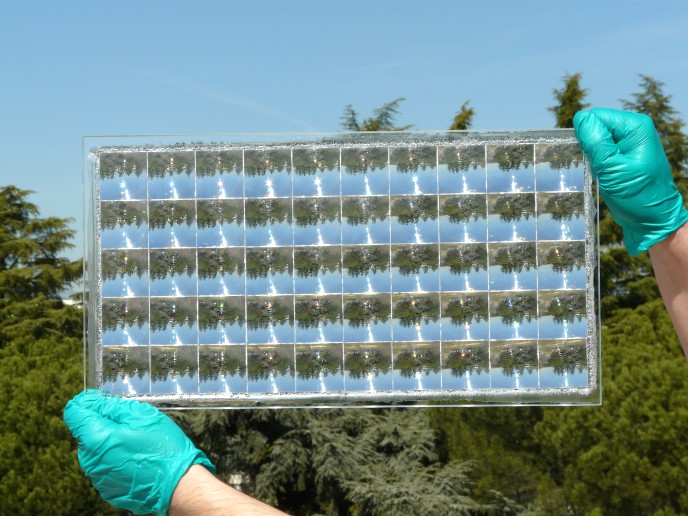

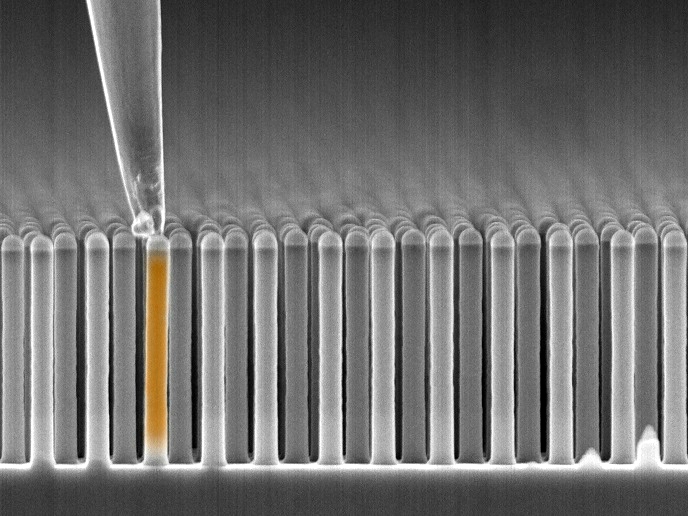

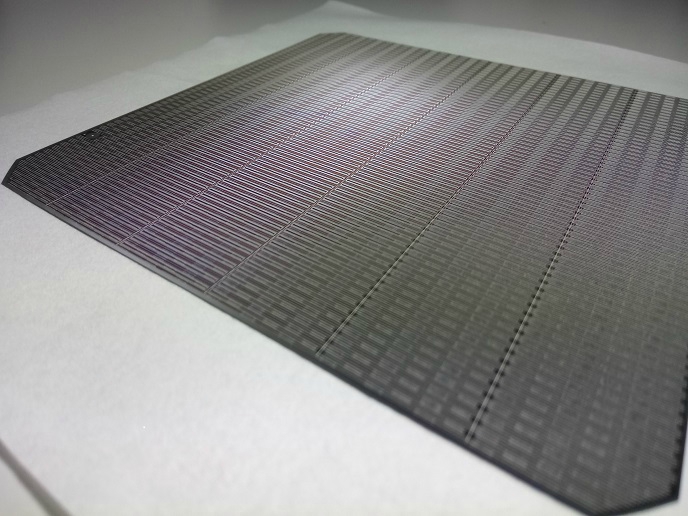

It is a well known fact that natural resources are limited. In addition, high growth rates of the developing countries resulted in a sharp increase of global oil consumption. Moreover, a number of environmental hazards result from constantly rising energy consumption. Among the so-called alternative forms of energy, solar energy is an ideal source. With the aid of silicon solar cells, solar energy is gathered and consequently converted to electricity. At laboratory scale, highly efficient silicon solar cells can be fabricated. The INDHI project has developed the corresponding industrial processes for massive solar cell production. Better solar cells, industrially fabricated, will substantially increase the use of solar energy. The selective emitter is the backbone of any solar cell. It is the quality of this selective emitter that basically determines solar cells' efficiency. The INDHI project partners have successfully developed a novel screen-printed selective emitter for industrial multicrystalline silicon solar cells. The emitter has been fabricated with selective printing on the substrate material of doped pastes. INDHI project partners used the commercially available Soltech P101 thick film dopant paste for the formation of the emitter. Several selective emitters have been obtained with resistance values ranging from twenty to a hundred Ohms per square centimetre of the emitters' sheet. The selective emitters formed in this work package of the INDHI project have been extensively optimised and tested. Control of the lateral diffusion of the doped paste, reflectance and characterisation of the properties of the junctions have been among the optimisation parameters. Efficiencies approaching twenty per cent have been achieved.