Germanium substrate: A promising platform for multi-junction solar cells

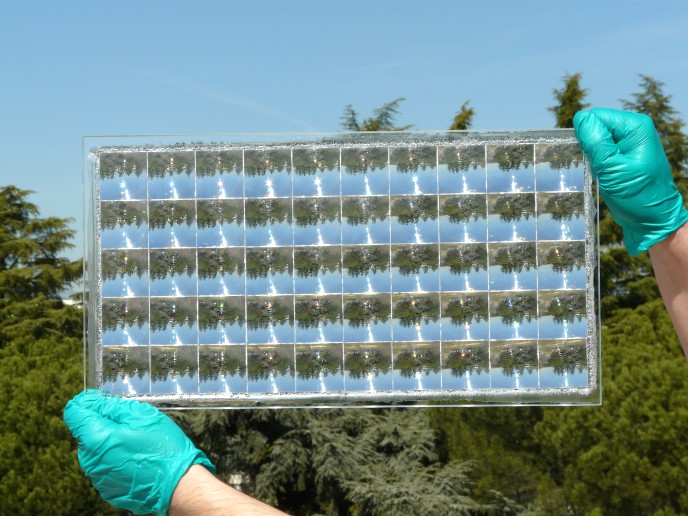

The world is looking towards renewable energy such as solar power to reduce greenhouse gas emissions and solve the looming energy crisis. However, developing high-efficiency solar cells that can convert a significant amount of sunlight into electrical energy at very low costs remains a significant challenge. Concentrator photovoltaics that use optics to focus the Sun’s power on high-efficiency multi-junction solar cells can play a large role in boosting solar power generation. This technology requires sub-cells with different band gaps to absorb different parts of the solar spectrum to realise high theoretical energy conversion efficiencies. High-performance mirrors or lenses can focus over 500 times more sunlight onto these tiny cells compared to conventional flat-plate photovoltaics. However, this technology requires further cost reduction. Perfect crystal matching Combining two technologies is a practical step for making concentrator photovoltaic systems more competitive with other forms of energy generation. This means taking a low-cost wafer and using it as a basis for forming many highly efficient multi-junction devices featuring various compound–semiconductor layers. “Matching the atomic spacing of successive layers is a crucial element when combining materials with certain band gap energies,” notes Dr Gerald Siefer, project coordinator of the EU-funded project CPVMatch. As he further explains, several methods, including metamorphic growth and wafer bonding, can be used to overcome the lattice mismatch. However, use of materials with the same lattice parameter is preferable to propelling multi-junction cells to higher efficiencies at low cost. Project researchers performed a successful proof-of-concept by using a germanium wafer and then adding a lattice-matched silicon-germanium-tin (SiGeSn) structure to form a 1 eV junction. Subsequent addition of III-V materials will allow upper junctions to be created leading to device architecture that can deliver very high efficiencies. “This is the first time that a high-quality IV semiconductor element – SiGeSn – is epitaxially grown on a germanium substrate on the same growth reactor as III-V semiconductor elements,” adds Siefer. Costing less than its counterpart Very high-efficiency photovoltaic cells partly implement indium phosphide based (InP) substrates to efficiently convert solar radiation into electrical energy. “The world record efficiency of multi-junction solar cells comprising InP as a substrate is 46 %. Still, this material is much more expensive than germanium,” notes Siefer. The new CPVMatch four-junction solar cell with a germanium substrate achieved 42.6 % efficiency. The project successfully developed and demonstrated other technical building blocks that – put together – will increase cell efficiency to 46 %. Overcoming the drawbacks of standard lenses Most concentrator photovoltaic modules are using the so-called silicone-on-glass (SoG) lenses. Although these lenses are cheap, they introduce chromatic aberration and their performance depends significantly on ambient temperature. Researchers experimented with achromatic lenses to reduce distortion. Despite their potential to yield a very high-performance device, they are expensive. To skirt SoG limitations and minimise costs, researchers focused on a cheap manufacturing process for achromatic lenses as well as smart, highly compact mirror-based concentrator photovoltaic modules. Both boast a host of advantages compared to standard lenses: no issues with chromatic distortion, coupled with higher solar conversion efficiencies. CPVMatch demonstrated concepts that cut solar-cell costs and boosted efficiency to ensure that concentrator photovoltaic systems become more competitive in the future. “High-concentration photovoltaic systems can achieve efficiency levels that flat-plate photovoltaics will never reach. What’s more, their demonstrated lower carbon footprint – ranging from 16 to 18 grammes of CO2 per kilowatt-hour of electricity produced – is of paramount importance for decarbonising the energy system,” adds Siefer.

Keywords

CPVMatch, concentrator photovoltaic, multi-junction solar cells, germanium substrate, silicon-germanium-tin (SiGeSn), lattice-matched, IV semiconductor, III-V semiconductor, achromatic lenses, mirror, optics