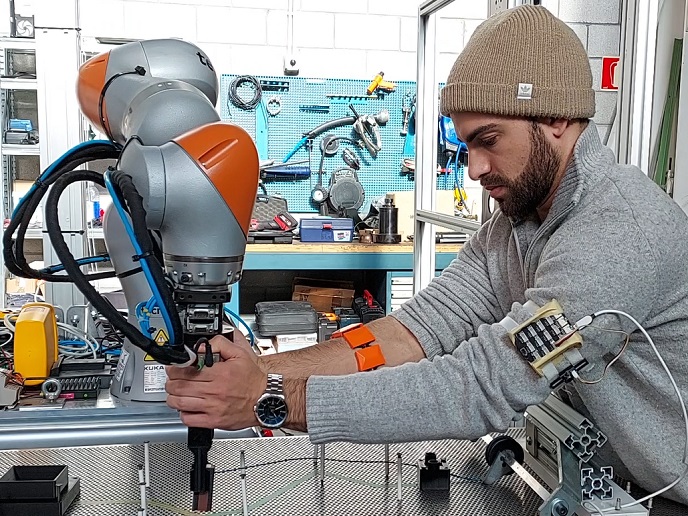

Co-created robots to handle complex manufacturing tasks

While factories of the future are anticipated to be fully automated, current robots struggle to replicate manual tasks such as handling complex materials and objects. “If Europe is to position itself at the forefront of complex manufacturing and stop the drift to countries with cheaper manual labour, we urgently need more adaptable robots,” says Gianluca Palli, project coordinator of the EU-funded REMODEL (Robotic tEchnologies for the Manipulation of cOmplex DeformablE Linear objects) project. Building on the previous work of WIRES (part of the EU-funded ECHORD Plus Plus project), REMODEL has developed dual-armed robotic tools with cutting-edge perception and interaction functions that can manipulate the wires and cables needed in some products.

Rethinking product design

REMODEL’s robotic tools were designed to handle objects whose shapes and movements are complex and unpredictable, and require small, dexterous and repeated actions. When done manually by humans, these tasks often require long, expensive assembly lines and can lead to repetitive strain injuries. REMODEL built on the WIRES project’s lab prototype for the automated assembly of cabling inside switchgear cabinets, power systems used to manage electrical equipment. As switchgears are stand-alone products, the production line has to be adjusted every time a new version is manufactured. Switchgear wiring for industrial plants was one of four industrial manufacturing use cases investigated by REMODEL, alongside automotive and aerospace wiring harnesses and quality inspection of manufactured tube-based medical equipment, such as catheters.

Human-inspired design

Inspired by the way humans assemble objects, REMODEL developed a dual-armed robotic solution, a relatively uncommon design on assembly lines. “Many tasks, such as shaping cables, requires control of two points, and, even if for two separate tasks, these often need to be accomplished simultaneously. So we developed ‘fingers’ for dual-armed robots capable of precision grasping,” explains Palli, a professor of mechatronics at the University of Bologna, the project host. While the project sought to adapt pre-existing hardware, to ensure simple integration into current workflows, in some places it became necessary to develop new components. “Before robots can manipulate objects, they have to be able to ‘see’ and ‘feel’ them,” adds Palli. “But most 3D sensors are not sensitive enough to detect thinner objects, such as wires, and tactile sensors are not yet advanced enough, so we developed our own.” Advanced software also helped compensate for sensor limitations. Machine learning algorithms were trained through exposure to a wide range of assembly tasks, in simulated and real environments. For more complex tasks, such as fitting wiring harnesses in vehicles, algorithms were developed with autonomous installation decision-making capabilities. The team’s industrial-scale prototypes are now almost ready for testing within factory environments. Switchgear cabling will be tested at IEMA in Italy, while wiring harness manufacturing will be tested for automotive at Elvez in Slovenia and for aerospace at Elimco in Spain. Harness installation will undergo tests at Volkswagen in Poland, while catheter quality inspection will take place at ENKI in Italy. Co-creation has been key to the project’s success, says Palli. “The workers who currently perform these tasks manually will be involved in quality assurance assessments and will be consulted on how their jobs could evolve in response to automation.”

Emergent production environments

Automated manufacturing not only helps reduce costs and worker injuries, but also contributes to wider EU ambitions, such as the circular economy action plan. More precise manufacturing makes more efficient use of materials, reducing the resources needed, as well as the need for remanufacturing to compensate for mistakes, while lessening pollution and waste. “Another benefit will be customisation,” adds Palli. “A highly adaptable system won’t need to be reprogrammed to accommodate new tasks, making manufacturing less linear. Robots won’t simply be built retrospectively to make a product, rather a product’s robotic manufacturing needs will be embedded into design from the start.” This more holistic approach will generate demand for new skills, creating job opportunities, if the right training investments are made. Combining other smart systems could also revolutionise how we build our material world. “When selecting components, designers could use internet of things technology to learn more about how they were made alongside their recycling options. This would help the circular economy by replacing ‘black box’ products, where it’s hard to know what technology is inside,” concludes Palli. The team are already exploring additional areas of potential use, such as packaging involving cables, tubes or wires. As REMODEL’s image sensing can detect clothes, another possible application is washing machine testing, for which the team developed a prototype.

Keywords

REMODEL, robot, cable, wire, manufacturing, automation, switchgear, sensor, algorithm, grasping, manual