Robo-inspector checks industrial tanks from inside

Industrial liquids, including volatile hydrocarbon fuels, are not produced on demand, but rather stored. Storage tanks corrode and degrade over time. To prevent failure, which would have catastrophic environmental consequences, the tanks must be inspected periodically. Traditionally, tank inspections have been highly disruptive and inconvenient. First, the liquid must be drained and transported. Then, inspectors must physically enter the tank, a toxic and dangerously explosive environment. The EU-funded TankRob (In-service intrusive Non-Destructive Testing of above ground and underground petrochemical storage tank floors and walls to detect corrosion) project developed a superior inspection system involving a robot. The robot had to be designed to safely operate in an explosive environment as the liquid will remain in the tank while the system operates. A key goal of the project was obtaining certification under Europe’s ATEX regulations, which are design codes used for equipment used in explosive environments.

Convenient and safe

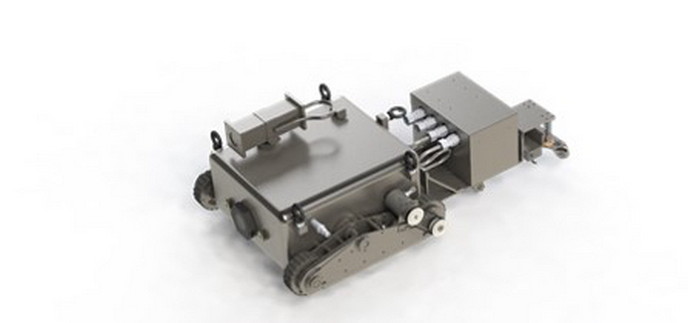

As Nico Avdelidis, project coordinator, explains: “TankRob is a crawler-type robot in three parts.” These are: the crawler, which operates inside the tanks; the controller station, positioned away from the tank; and an umbilical cable, which connects the other two parts. “The crawler assesses the inside of the tank while it is full of liquid.” The crawler is essentially a stainless steel box, approximately 50 cm square, and about half that in height. It resembles a mini armoured vehicle. Independently driven wheels on each corner provide traction on slippery surfaces. A rotating sonar pod on the top helps the device locate itself inside the container. The front of the robot has a small camera window, and powerful LED lights either side, so the operator can see in dark conditions. The operator sets up a safe distance from the tank. To avoid risk of a spark detonating the volatile atmosphere, the robot is powered off while being lowered into the tank. Then the machine performs an intrinsically safe self-check, measuring internal and external pressure and temperature. If the temperature is below 40 °C, and if the pressure sensor indicates that the robot is safely on the tank bottom and not leaking, then the device will be powered up for the inspection.

Assessing tank walls

The crawler tows non-destructive testing equipment, which determines the thickness of the tank wall. “The robot can either perform a complete inspection of the tank to identify areas of corrosion, or can be driven to a previously identified area of interest to determine whether the corrosion has accelerated since the last inspection,” adds Avdelidis. Once the inspection is complete, the operator drives the robot back to the insertion point for recovery. Then the robot is powered down again (except for the safety system), and winched out through the liquid and explosive gas layer above. The robot and umbilical are cleaned, then removed from the dangerous environment. Following extensive testing, TankRob achieved ATEX certification, and is now ready for commercialisation. The team will initially target the EU market, and is already in discussion with potential customers in Greece and Cyprus. The project will eventually target a worldwide market. TankRob reduces the risk of chemicals escaping during transport and causing environmental harm. The tanks also no longer need draining, saving time and money. Most importantly, the new system reduces risk to the inspectors, who no longer have to enter the tank at all.

Keywords

TankRob, robot, tanks, crawler, inspection, explosive, industrial liquid, safety