High-tech stretchable lightweight tape could benefit industries from aerospace to automobiles

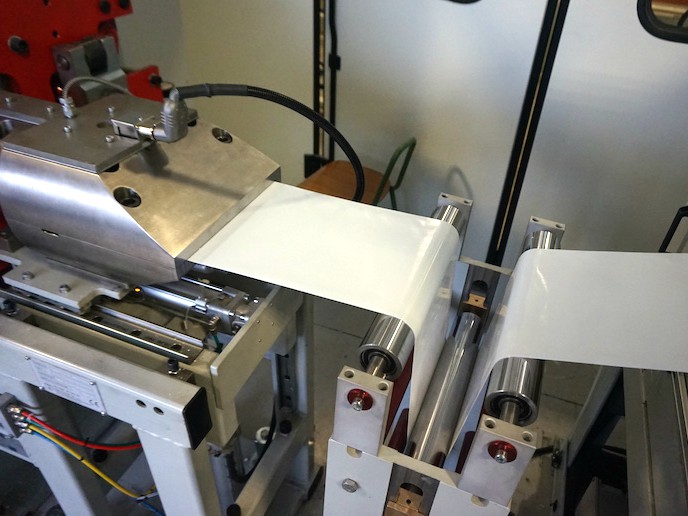

The Horizon 2020-funded ProPApp project improved and streamlined the production of an old and widely used polymer, bringing the technology into the space age. Polytetrafluoroethylene (PTFE) is a synthetic polymer created in the 1960s, commonly known by its biggest brand name, Teflon™. It’s used widely in everything from cookware to cable production, often taking the form of a versatile coating – the non-stick protective layer in many frying pans, for example. PTFE’s unique chemical bonding gives it characteristics of extreme durability. It can withstand a wide range of temperatures, remaining stable from -50 °C to over 350 °C. It is acid-resistant and non-sticky. Its long life makes it ideal for applications across many industries. But it is dense, and difficult to process. What’s more, the techniques to do so are not very well known, meaning that although PTFE is a useful material, its uses have been constrained. This is particularly true of the tape form, produced for many industries, as PTFE tape doesn’t expand further than 20 %. The ProPApp project, carried out at Macchine Speciali in Milan, Italy, designed a new production line for the creation of a new, stretchable and expandable tape, E-PTFE. The powders used to create the tape are bi-oriented, meaning that the material can be stretched lengthways, and horizontally too. This tape is stretchable in all directions, making it far more flexible. It can be stretched down to a thickness of just 0.01mm making it applicable in even more scenarios in a variety of sectors such as aerospace, automotive, petrochemical and medical. The new tape will also be lighter and cheaper. The fact that it is resistant when stretched in any direction means that it can be treated further, explains Mr Giovanni Sironi, General Manager at Macchine Speciali and ProPApp project leader. “It can be tensioned in both directions, bringing it to the desired thickness to obtain a gradually thinner tape, until it becomes a membrane, permeable to air but impermeable to water.” The lightweight version of PTFE is 50 % less dense and will have high-performance uses in electrical and power cables. Now that the project has been completed, the team would like to scale up production and adoption into other countries, selling specialised plants for the construction of the tape. Two of these have already been sold, says Sironi. “This new element to our business will permit us to come up with new solutions as we develop this cutting-edge technology. But we haven’t lost sight of the traditions we have built up over 20 years which have enabled us to export our machinery across the world.” Formed in 1996, Macchine Speciali have become production experts in the cable industry. They pride themselves on listening to customer feedback to inspire innovation in new products, and for the past two decades have been investigating the production limitations of PTFE, which is how they devised the idea for E-PTFE. They welcomed the support that the EU provided for the project, giving them the boost to refine and scale up production. “Horizon 2020 is definitely a valuable contribution for companies that want to innovate to propose something new and attractive – and why shouldn’t we aim to improve the world of work, industry, and society? Our project would be very proud to be able to achieve these goals too.”

Keywords

ProPApp, PTFE, Teflon, tape, stretchable, resistant, aerospace, automotive, medical, cabling, cables, design, Italy