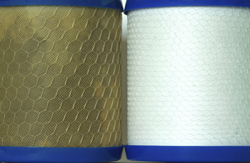

A self-cleaning filter membrane

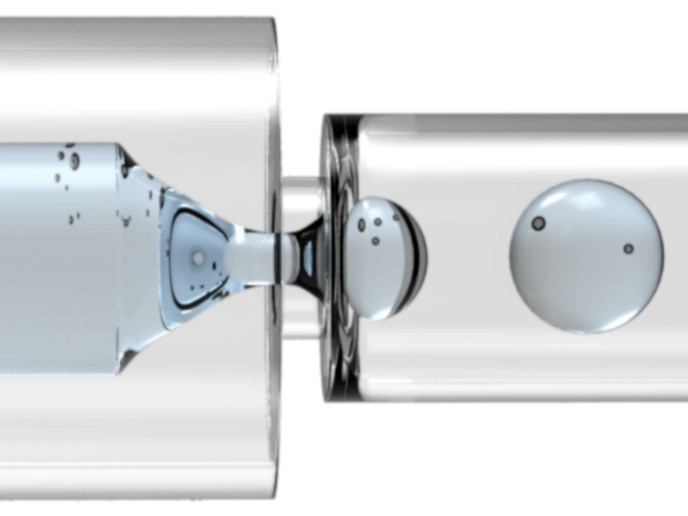

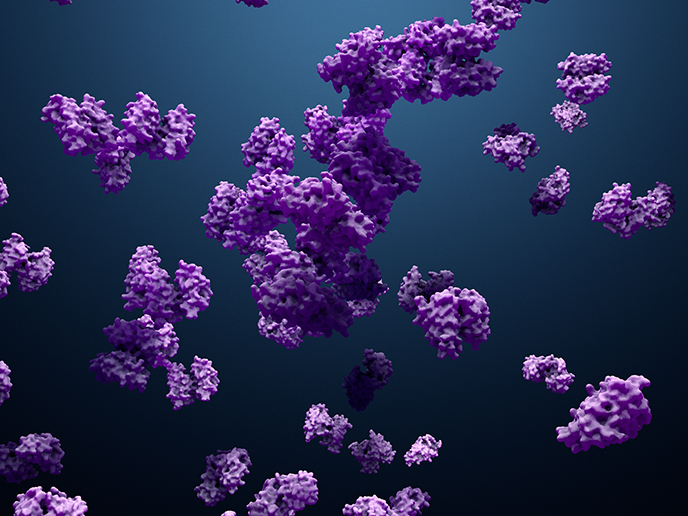

Biofilms can reduce the efficiency of membranes by up to 50 %, and increase cleaning costs. In addition, membranes need to be replaced often due to fouling, increased membrane pressure or constant cleaning. The EU-funded CONDUCTMEM project was envisioned to build a conductive membrane that destroys biofilms through the production of oxidising chemicals on the membrane surface. The project first developed 10 different conductive membranes with differing pore sizes, conductivity and flow rates. These were tested to see if they could remove biofilms as researchers expected. The best membrane was chosen and installed into a laboratory-scale prototype filtration device, which successfully destroyed biofilms during short filtering runs. A demonstration-scale prototype with an automated control system was then built and installed in an industrial wastewater filtering plant. After several adjustments to operating conditions, the prototype was deemed successful in destroying biofilms during continuous operation. When implemented, the CONDUCTMEM device will save operational costs and help companies comply with increasingly stringent water use regulations in the EU.

Keywords

Biofilm, fouling, conductive membrane, wastewater, filtration