An alternative to pasteurisation

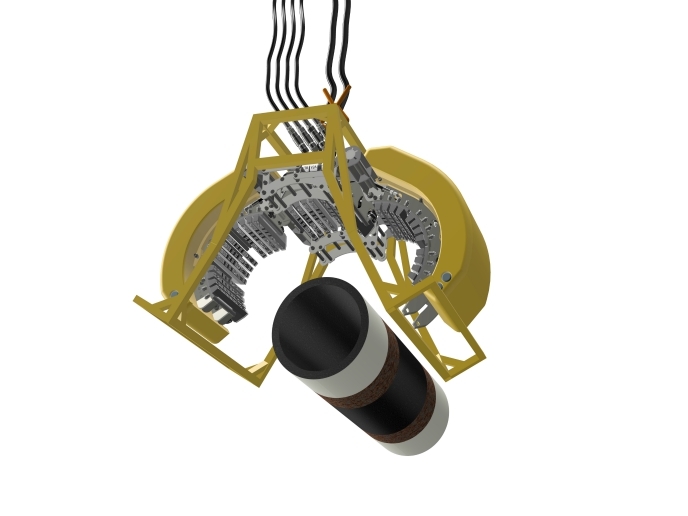

Rural populations across Europe often still drink raw milk, and other consumers prefer unpasteurised milk, believing it to have a higher nutritional value. However, the consumption of raw or inadequately pasteurised milk has been associated with foodborne illness such as Salmonella. Pasteurisation prevents this by killing bacteria, yeast and fungi, but the high temperatures used also change the taste, and reduce the levels of vitamins and bioactive compounds. The EU-funded SMARTMILK initiative investigated an alternative milk treatment technology that would retain the natural flavours and components of milk, while ensuring consumer safety. The SMARTMILK prototype combines a pulsed electric field (PEF) with ultrasounds at moderate heat. This approach employs milder conditions to inactivate microorganisms, but results in a similar shelf life achieved with conventional pasteurisation. Project developers were committed to making the system affordable, robust and easy to maintain. In the initial stages of the project, they surveyed milk processors, cheese makers, yoghurt manufacturers and dairy equipment providers in order to define the industrial specifications. From this, a modular prototype unit that can be easily transported and used in typical industrial dairy plants was developed. The functionality and technology of the system was validated in a pilot plant facility in Spain. It was tested for the treatment of milk, as well as for its suitability in cheese making and yoghurt manufacture. The results of the validation tests indicated that the SMARTMILK system can be used to inactivate the microorganisms present in the raw milk. The sensory characteristics of pasteurised milk cheese were preferred over SMARTMILK cheese. Unlike conventionally pasteurised dairy products, SMARTMILK yoghurt showed lower viscosity and a smoother texture. At this stage, the prototype proved the concept in industrial conditions, but it is not yet suitable for systematic industrial exploitation. During the post-project phase, more work will be done to scale the technology up to commercial scale for market exploitation. The potential for this system to be used in the treatment of other liquid products such as fruit juices, wine and beer is high. The SMARTMILK approach is expected to benefit consumer safety and confidence, which could in turn improve the competitiveness of thousands of European milk processing small-to-medium enterprises.