The sound of plastic

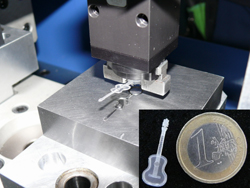

Most people are familiar with the ultrasound technology (sound waves beyond those of human hearing) used to map images of foetuses in hospitals. The same technology has many other applications, such as welding and moulding plastics, because of the heat that ultrasound technology can generate. ′New process and machinery for microparts moulding based on ultrasound excitation′ (Sonoplast) is an EU-funded project that is working on a completely revolutionary concept of plastification and moulding for very small plastic parts. It is based on the use of ultrasound technology to respond flexibly, reliably and cost effectively to the needs of suppliers for the production of complex parts. In more specific terms, the project is developing the first ultrasound-based moulding machine for the production of plastic parts at the micro- and mini-scale size. Development of this machine requires a new concept of mould and plastic feeding system that fits its ultrasound and mechanical features. Thus, Sonoplast is working on the machine's product design, mould making and injection moulding, among other features. Previous trials have already confirmed that it is possible to fill tiny cavities in a mould with plastic melted by using ultrasound technology. The equipment provides heat for melting the polymer while producing the required filling pressure. Taking only a few tenths of a second, the energy provided by the ultrasounds also allows for filling the mould while applying significantly less pressure compared to the solutions currently in use. The new technology also eliminates the plastification unit, common in traditional plastics manufacturing. All these advantages help reduce cost and increase efficiency during production. The project had to overcome many challenges. It studied how ultrasounds affect the melting properties, and determined how to achieve the best results in this respect. It also worked out all the details in developing a mechanical concept and novel moulding techniques for the ultrasound moulding machine. Sonoplast also developed a new feeding system, followed by process-control strategies and systems,, including implementation of a sensor system to ensure process reliability. Automation was also studied and incorporated, rendering the equipment as efficient as possible. In a nutshell, Sonoplast′s original aim – the development of the first ultrasound moulding machine for the production of micro and mini plastic parts – has been successfully achieved. The new technology positions Europe as a leader in manufacturing minute plastics, and will have a positive impact on a myriad of applications.