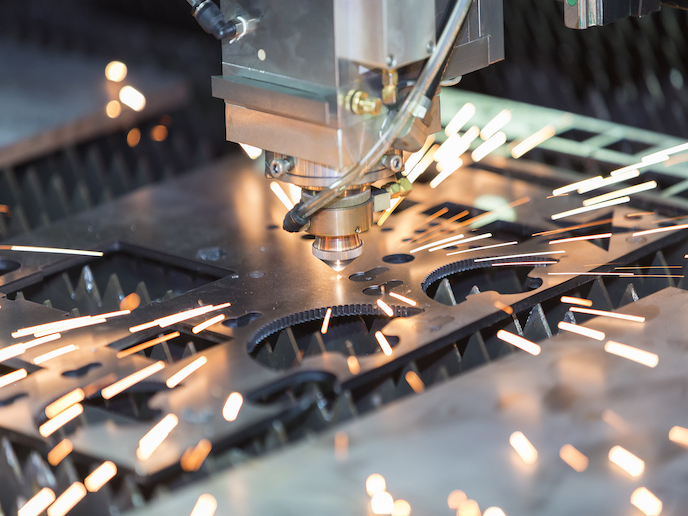

European expertise in machining applications

Grinding is an essential machining procedure. Unfortunately it consumes large amounts of energy and materials. The GROWTH Programme invested heavily in the development of new grinding technology. The ENGY project, which brought together experts from both industry and academia from across Europe, is a prime example. Saint-Gobain Abrasives Ltd., a leading manufacturer of grinding tools headquartered in the United Kingdom, designed new grinding wheels and then constructed them from Cubic boron nitride (CBN), an extremely hard material. They managed to extend component life while at the same time reduce the amount of energy consumed by the equipment. Encouraged by these results, Saint-Gobain Abrasives Ltd. Attempted to transfer the new technology to grind hardening. They concluded that further testing is required to resolve issues related to control before the procedure can be implemented in an industrial setting. The structural advances achieved during ENGY were, however, deemed mature enough for immediate use in several different grinding applications. The initial feedback obtained by Saint-Gobain Abrasives Ltd. Indicated that the new grinders lasted up to three times longer than their conventional counterparts. Furthermore, it was possible to maintain good geometry without causing burns.