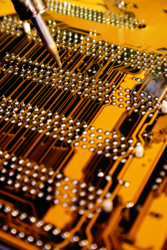

Test board for evaluating lead-free solder

The use of lead in the manufacture of electronic and electrical equipment was prohibited under the Restrictions of Hazardous Substance (RoHS) Directive. The metal was banned due to its detrimental impact on human health and the environment. In order for a ban on lead in solders and finishes to be effective a suitable replacement material needed to be developed. The EFSOT project created a test board for evaluating the reliability of the new lead-free solder paste. The paste can be applied to a broad spectrum of applications, ranging from consumer to automotive electronics. The test board was used to validate different types of very fine pitch printing and soldering. It was also used to confirm the solder's suitability for a number of other more specific properties. These included ease of cleaning, insulation, power components soldering and compatibility with different finishes for printed wiring boards. the design of the test board reflected the different standard patterns of three industrial project partners, which were compared. The industrial partners used their designs to manufacture boards and validate a range of processes for lead-free solder. Researchers identified the design which gave the best results for high volume production using automated optical inspection. the EFSOT project involved collaboration between technical and environmental experts who focused on the entire life cycle of solder. The life cycle extended from solder production to the manufacture of printed wiring boards and the reuse and recycling of electronic equipment.