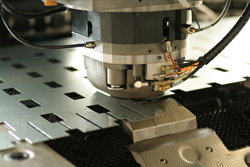

Dry lubricants for stamping dies

The goal of the ECOSTAMP project was to develop a dry lubricant as an alternative to the toxic liquid lubricants used in sheet metal stamping. Exposure to the lubricants can result in skin diseases including dermatitis, tumours and changes in skin pigment. Reduction of harmful liquid lubricants can also contribute to the EUs policy for sustainable development and help European companies to achieve certification for the environmental management standard ISO 14001. Furthermore, significant cost savings can be achieved by managing and reducing the negative environmental impacts from sheet metal forming lubricants. Researchers from the ECOSTAMP consortium used thermal spraying to coat the surface of stamping dies with a composite material made up of solid lubricant. Different amounts of graphite and chromium carbide were mixed with a nickel-chrome metallic matrix before being deposited onto a steel substrate with an atmospheric plasma spray. Following the spraying of the dry lubricant on the steel, results indicated only minor levels of wear and a low friction coefficient. The ECOSTAMP research team ascertained that the friction coefficient was reduced when the graphite content was increased. The optimal level of wear resistance was achieved with a graphite content of 35% by volume.