New concepts in layered oxide sensor structures

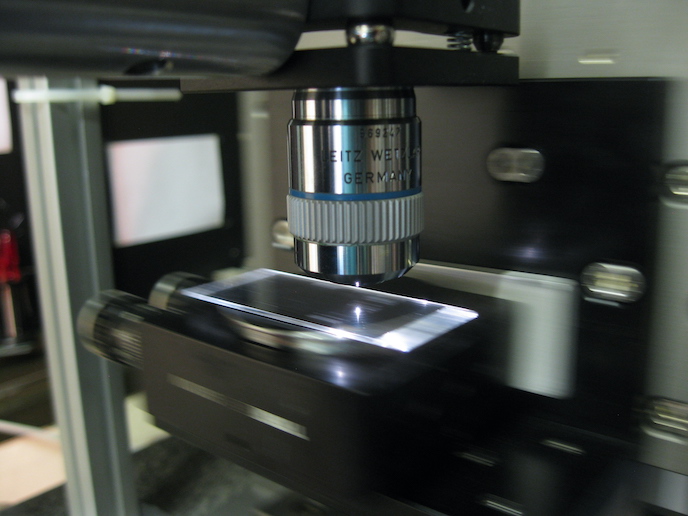

The aim of the NANOPHOS project was to develop new technology for optical metal/oxide multilayer sensors for detecting gaseous agents and pollutants. The work addressed a number of issues related to the monitoring of air pollution and improvement of health and safety and industrial processes. Areas of application for the new sensors included natural gas processing, storing of pharmaceuticals, oil and gas exploration and improved monitoring of the food chain. A multilayer structure was created using magnetron sputtering to deposit a film of metal oxide. Platinum, palladium, gold or zinc, and silicon or zinc oxides were then deposited from metallic targets while using argon or reactive argon/oxygen sputtering. During the dry etching process hard metal or silicon masks were developed and successfully applied. The desired pattern was initially developed in the hard mask and then applied to the metal/oxide multilayers. The mask protected selected areas of the underlying substrate during the process. The mask was removed and the diffractive structure below revealed. A different approach was developed in order to pattern metal/oxide multilayers with refractory metals that were difficult to etch. This process used lift-off lithography and deposition of metal/oxide multilayers. During the lift-off lithography process the substrate was covered with material so care was taken to avoid overheating whilst sputtering was carried out.