Lowering the barrier for innovation in flexible electronic components

The digitalisation of the manufacturing industry, known as Industry 4.0 is held back in Europe by the high cost and limited capacity of technologies such as 3D printing and laser processing. To competitively develop and manufacture embedded components such as flexible circuit boards, Europe must increase production capacity of the prerequisite functional nanomaterials. Achieving this relies on the digitalisation of supply chains, to lower manual labour costs, while also speeding up the development process using advanced machine learning and artificial intelligence techniques. To meet the challenges of this digitalisation, the EU-supported project www.lee-bed.eu (LEE-BED) (Innovation test bed for development and production of nanomaterials for lightweight embedded electronics) has developed an Open Innovation Test Bed, designed as a one-stop shop catering to the whole supply chain. “Our demonstrations have created many exciting novel solutions, which will help us sell the LEE-BED services and pilot lines,” says project coordinator Zachary Davis from the www.dti.dk (Danish Technological Institute) in Taastrup, the project host. It has been validated across four industrial case studies so far. One opportunity currently being explored with Swarovski will pave the way for a larger collaboration between Swarovski and the automotive industry, delivering next-generation interior electronic panelling.

Patenting assistance, business planning and standardisation services

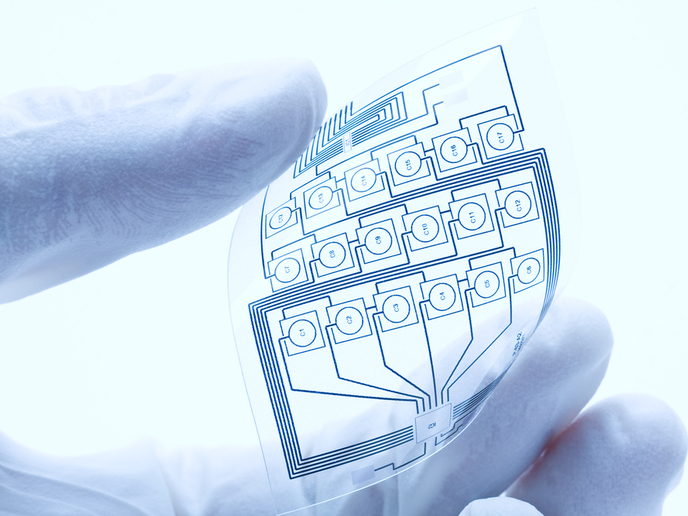

Customers of LEE-BED’s open test bed can access the system through a single entry point webpage, which splits their user journey into three phases. The first provides technological and economic assessment, using information about a client’s operation to offer insights about the feasibility of new ideas. Building on these findings, the second phase gives access to pilot line technologies, covering: the development and upscaling of tailored nanomaterials; the development and production of nano inks, adhesives and composites; and prototyping and piloting of printed and embedded electronic circuits and sensors. These aim to provide a development time of under 6 months. The third phase concentrates on knowledge transfer, providing clients with tools for commercialising their products. This includes intellectual property rights and patenting assistance, business planning and standardisation services. As well as developing prototypes of flexible transparent lighting and touch panels for Swarovski, case studies include: embedding flexible electronics into plastic panelling for automotive developer MAIER; solutions for embedding asset tracking and temperature sensing into composite structures for construction company ACCIONA; and embedded temperature and humidity sensors for smart packaging applications for Grafietic (website in Spanish). “These cases allowed us to provide a range of prototypes and demonstrations,” adds Davis. “For example, we developed silver nanowires, formulated into a printable ink, alongside a process to create highly transparent electrical circuits with LED and touch sensor functionalities.” The project also developed more bespoke services, such as providing information about funding options for SMEs lacking the capital for pilot projects, as well as proposal coordination and writing services.

A greener embedded and printed electronics industry

Currently, LEE-BED’s services can be accessed freely while the team is further validating LEE-BED’s overall procedures, through an additional 10 end user case studies and continuing to develop new technologies and pilot lines. In response to increased demand, they are furthering work on 3D electronics printing. “Thanks to an open call, we’ve had interest from several companies, which we believe will lead to paying projects, especially linked to our transparent panelling and interactive lighting and textile-embedded electronics,” remarks Davis. “We aim to have several revenue-generating pilots finished by the project’s end.” They also remain vigilant for more sustainable materials and recycling processes to make their own operations, as well as the entire embedded and printed electronics industry, greener and more self-sufficient.

Keywords

LEE-BED, digitalisation, nanomaterial, printed electronics, lighting, touch sensor, automotive