Online monitoring delivers beer and bioethanol production efficiencies

Beer-making and grain-based bioethanol processes are surprisingly similar. They both involve the conversion of carbohydrates (sugars and starch) into ethanol using selected strains of yeast. But whereas the beer-making process aims to produce a consumer product of consistent taste and quality, the bioethanol process mainly focuses on production yield. “Both processes consist of a ‘mashing’ step in which the grain is mixed with water and heated,” explains OptiSpec project coordinator Christian Nybo Petersen, co-founder and technical engineer at Specshell, Denmark. “This becomes a porridge-like slurry, in which the starch is converted into fermentable sugar.” This mash is then turned into alcohol in a subsequent fermentation step. In the bioethanol process, the resulting fermentation stream is furthermore distilled into pure alcohol. To date however, online monitoring of this conversion process in both beer and bioethanol production has proven difficult to achieve. An automated system that provides detailed insight on compositional data, such as the level of sugar concentrations throughout the process, could help manufacturers achieve more accuracy and better production efficiencies.

Improved online monitoring

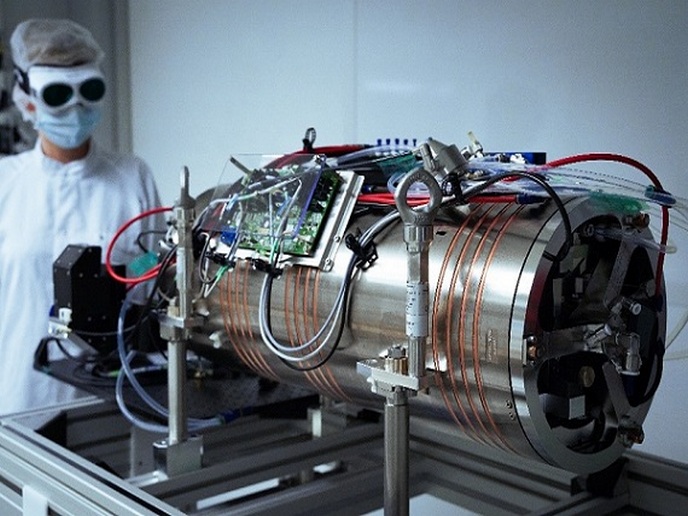

The Danish start-up Specshell was founded in 2014 to achieve just this. “Our initial concept was to adapt mid-infrared spectroscopy to suit the online monitoring of the beer mashing process,” notes Petersen. “In 2018, we were able to launch our first industrial product onto the market.” This instrument however could not be applied to the bioethanol process. Nor was it fully developed enough to provide real-time online recommendations to help manufacturers make adjustments during the beer mashing process. The EU-funded OptiSpec project was launched in October 2019 to address these two issues. The project consisted of four specific tracks. The first involved modifying the physical design of the instrument to make it fit better within the industrial environments of both processes. Secondly, the project team developed predictive capabilities by applying machine learning technologies to the beer mashing stage. “Third, we developed the data set needed for our instrument to be applied during bioethanol fermentation, and adapted the user interface for use by this specific industry,” says Petersen. “The final track involved industrial validation.”

Ready for industry

The project was successfully executed according to plan. “The ethanol fermentation model was repeatedly demonstrated to work in real-life industrial conditions,” Petersen adds. “Of course, no project comes without challenges, and we had to reprioritise certain elements. Also, the COVID-19 situation forced us to relocate our industrial validation efforts closer to our home base, which is Europe.” The success of these trials means that the new instruments are ready for commercialisation. “We expect significant new economic activity,” remarks Petersen. “We are confident that we now have technologies to serve both the global brewery and bioethanol sectors.” According to Petersen, commercialisation in the brewing industry will take place through existing commercial networks, while new contacts will be built within the bioethanol sector. “Initially, we intend to target the European as well as the North American bioethanol producers,” he says. “Ultimately, this project will bring benefits to both sectors. The online monitoring of mashing and fermentation processes is something that only a few years ago was just a dream.”

Keywords

OptiSpec, bioethanol, beer, ethanol, brewing, yeast, carbohydrates, fermentation