Intelligent robots can learn to recycle hazardous hardware

Electronic waste is the fastest-growing waste stream in the EU, yet less than 40 % is recycled. Dismantling smartphones, computers and other household gadgets is intricate and potentially dangerous work for humans to carry out. Many of these devices were built with the assistance of advanced robotics. Could these machines also help with their disposal? Robots are typically programmed to execute tasks within a limited repetitive range. The EU-funded IMAGINE (Robots Understanding Their Actions by Imagining Their Effects) project has developed an intelligent system to enable a robot to ‘understand’ how to disassemble a device version it has not encountered before. Even a small device can have hundreds of screws, which can be laborious to manually take apart. “As a result, whenever these expensive recycling procedures arise, in practice recycling just doesn’t happen,” explains project coordinator Justus Piater, head of the Digital Science Center at the University of Innsbruck, Austria. Instead, it can lead to disposal that is a risk to health and the environment, he adds. The 4-year project raises a robot’s capabilities by improving adaptability, perception and autonomy in making decisions by combining machine learning with physics-based simulation of what the robot is likely to encounter with a device. “Our biggest breakthrough is the highly integrative aspect of the system to partially or fully disassemble objects it has never seen before, in a way that could not have been planned or programmed from scratch because the information was just not there,” says Piater.

Intelligent system

A major novelty is that the system can trigger physical simulation to estimate the usefulness of certain actions, Piater explains. “If you can estimate this in advance, then you can gather experience and statistics that describe the utility of those actions so that, next time around, it can help you make a better decision. The system learns from this.” Physics-based simulation generates and visualises objects and their interaction with the environment. Camera images of a device are analysed to detect opportunities for action, known as ‘affordances’ which can include unscrewing, levering, pushing away and turning, shaking and so on. Perceptual capabilities, like detecting or recognising objects or estimating the position and orientation of parts, were enhanced by the IMAGINE team. They also developed new screwhead detection systems, specific affordance detectors and detectors for wiring inside electronic devices. “We have state-of-the-art perceptual, especially visual perception, capabilities and we developed specific new functionality,” Piater notes.

Innovative planning

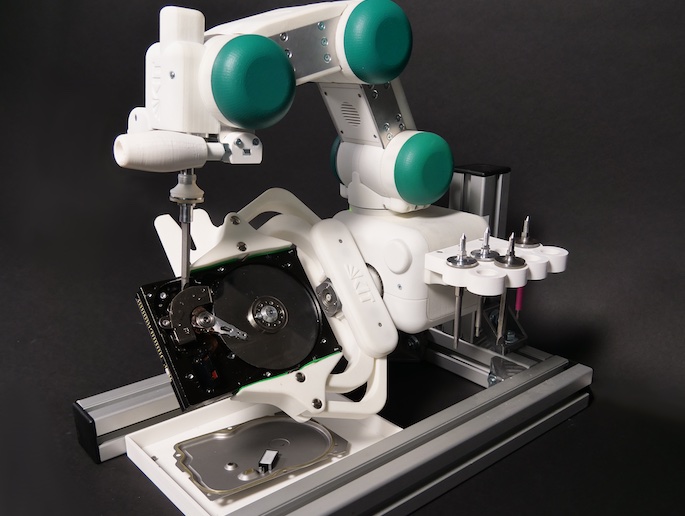

In terms of planning, Piater says: “A special planning system was developed which decides what action to take next, not only by choosing one of the affordances to act upon, but also by looking at the future and coming up with as much of a plan as possible.” This can be based on simulated and real interaction. Existing planners are formulated mathematically to construct a complete plan or no plan at all. “If they cannot get to the goal then they have no way to figure out whether any action would be useful. But the planner developed by the IMAGINE team knows how to make progress even if it cannot produce a full plan, just like humans would do,” he remarks. A sophisticated multifunctional robotic gripper with a built-in tool changer was specially designed for disassembling small electronic devices. The demonstrator system was trained to dismantle computer hard drives and can also handle some types of graphical processing unit. “We let the robot perform the entire operation many times and analysed the state before and after and let the robot learn from that experience,” Piater adds.

Keywords

IMAGINE, robots, recycling, hazardous hardware, e-waste, electronic waste, environment, machine learning, simulation, hard drives, electronics