A sensor network to reduce the risk of tap water contamination

The Food and Agriculture Organization (FAO) says that 38 % of water bodies in the EU are under significant pressure from agricultural pollution. Of course, most European regions have a system in place to prevent contamination from reaching tap water: Farmers are asked to keep a record of their pesticide consumption, and sampling at critical locations is undertaken on a regular basis. But what if any contamination event were to occur between these samplings? The hard truth is, in 2021, people are still getting sick from drinking tap water, and this costs society some EUR 220 million every year. “From our point of view, the solution is to provide a tool that can sample continuously thanks to a dense mesh network of sensors,” notes Lars Krangnes, CTO at Cautus Geo and coordinator of the CoPs (Continuous hazardous water Pollutants sensing in the environment) project. “With such a network, we can quantify the contamination, identify which contaminants are present, locate the source of contamination, determine where it’s heading and investigate whether it’s a persistent problem. It’s the ultimate way to reduce chemical contamination and prevent outbreaks.” CoPs’ three project partners successfully developed such a solution by combining their respective expertise in groundbreaking electrochemical sensors, miniaturised electronics and geo-monitoring hardware and software. The resulting system tracks the unique fingerprint of chemicals contained in pesticides and fertilisers: It records these signals under controlled conditions before studying variations in the environment. “The sensors are the heart of the system. They have been uniquely designed to target each chemical of interest and can identify them within seconds to minutes. The system also includes a new type of data logger that controls and powers the sensors while sending the data to a cloud-based system for further processing and presentation of the results. We’ve used the latest IoT technology to create an all-round, user-friendly and intelligent solution,” Krangnes explains. The system is also environmentally friendly. Unlike other products on the market, it does not require chemical reagents so does not generate any chemical waste.

Towards a launch in 2022?

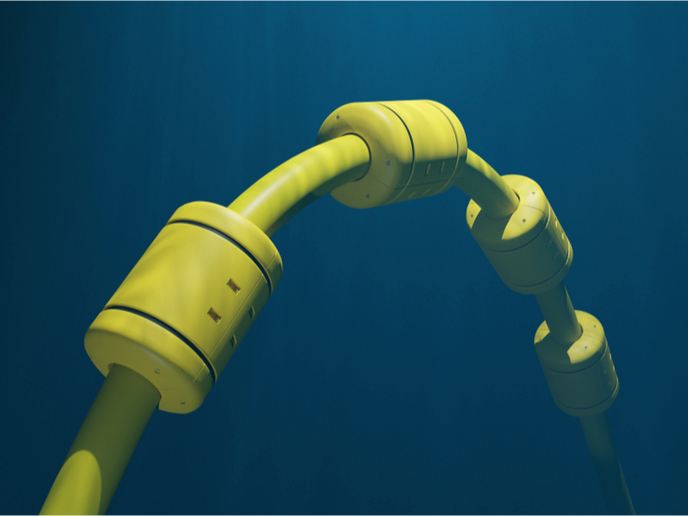

With the system now operational, project partners have been focusing on optimisation. They are notably working to increase the sensor’s lifespan so that future customers can use the system with minimum maintenance. “We are working on the third-generation prototype and we are aiming for field testing in summer 2021. Once this is done, we’ll need 6 months to gather user feedback and get ready for the first launch,” Krangnes says. The CoPs solution was extensively tested in the lab to validate results and get the best possible performance. “It’s a very important process. For example, part of the CoPs solution is submerged and contains very sensitive electronics and sensing parts. A simple moisture leak could result in system damage. To prevent such a scenario, we need to test the system under higher pressure than what it is designed for in order to ensure that the design will withstand extreme conditions and that the customer will not face issues,” Krangnes concludes. Now that it’s done, the team intends to deploy beta version prototypes for large-scale testing in relevant environments.

Keywords

CoPs, sensors, tap water, contamination, monitoring, cloud