X-ray-based system checks integrity of flexible risers for floating offshore platforms

Floating production systems are increasingly being used as oil and gas exploration and production move to deeper waters such as the Gulf of Mexico, offshore Angola and Brazil. Floating systems are deployed in water deeper than 200-300 m but cannot be connected by rigid steel pipes to the wells on the sea floor. In these situations, flexible risers are used to transport the oil and gas to the floating platforms above. Around 12 000 km of these complex multilayered composite pipe structures are installed worldwide and require continuous inspection. The EU-funded RiserSure project developed an automated flexible riser inspection platform that employs a novel subsea digital radiography detector to identify damage. It does so by performing 360° scanning around the riser at every point along its length.

A new approach

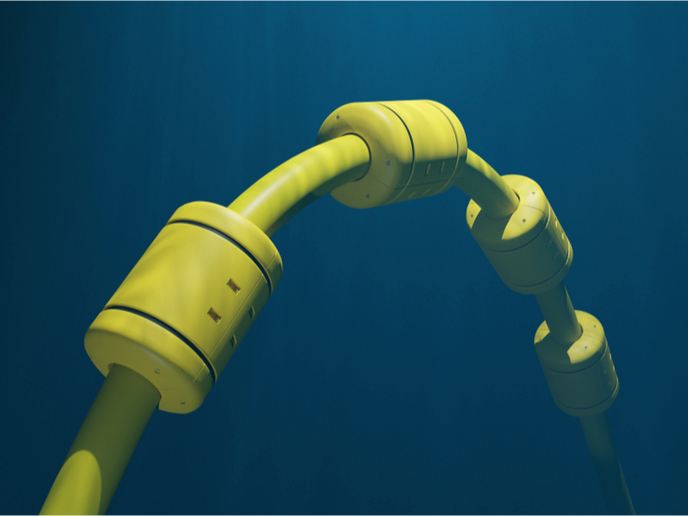

Currently, non-destructive testing (NDT) techniques cannot reliably assess the condition of flexible risers until it is too late and a failure has occurred. Hence, NDT solutions are receiving increasing interest across the globe to minimise the risk of equipment failure, reduce costs of equipment downtime and, most importantly, prevent environmental disasters. Furthermore, the NDT techniques employed to date require removal of the flexible protective coating from the riser and cannot penetrate all the layers of the pipe. “One answer is radiography, which is widely used in medical diagnostics (X-rays) and offers the ideal solution as it penetrates through all the layers in the riser structure, giving a complete picture of its condition,” says Nico Avdelidis, project coordinator. Consortium members therefore harnessed their extensive expertise in underwater robotics, NDT, marine detector technology and commercial software to develop an integrated system that uses a novel subsea digital radiography detector capable of 360° scanning of flexible risers using X-ray technology. “The system can be deployed and operated entirely remotely, with no need for divers to be present during the deployment and operation stages,” explains Avdelidis.

Multiple benefits

The RiserSure system can be used for regular monitoring of flexible risers and identifying defects/damage well in advance of any potential contaminant leaks, Moreover, the rapid commercial deployment of RiserSure results and delivery of new services will translate to significant savings for operators in the oil and gas industry. By reducing downtime and the incidence of costly and environmentally damaging leaks and failures, the system will at the same time improve the safety of offshore operations. Project partners forecast that if 70 % of flexible risers are inspected every 3 years there will be a market for nearly 250 machines worldwide by 2023. It is anticipated that if RiserSure is rapidly brought to market, thereby outpacing the competition, there is an opportunity to capture at least 30 % of this market. “It will also enable the early technology adoptors to become leading suppliers of equipment and services for automated underwater inspection and robotics for the global offshore engineering sector,” Avdelidis points out.

Keywords

RiserSure, flexible riser, oil and gas, offshore, NDT, X-ray, radiography, subsea, non-destructive testing, underwater inspection