Bringing nature’s own technology to the fore of the clean water revolution

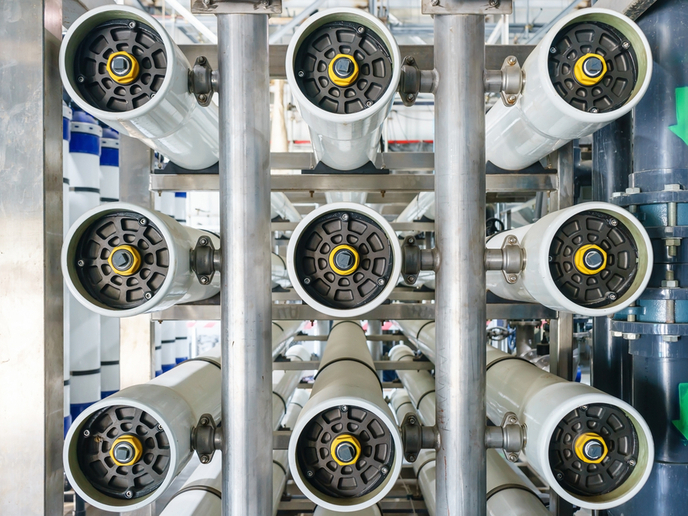

While Europe is largely considered to have adequate water resources, climate change has made water scarcity an increasingly widespread phenomenon. Regions notably in southern Europe suffer from water stress and resort to desalination of brackish and seawater to secure their supply of freshwater. With increasing demands for freshwater anticipated in the coming years, the desalination industry is expected to grow. Reverse osmosis (RO), currently the most widely used desalination technology in Europe, exploits the osmosis principle, removing salt from seawater by transferring water through a series of semipermeable membranes. This is an energy-intensive process, however, which contributes significantly to the continent’s carbon emissions, as well as releasing by-products, such as brine, which can be detrimental to the environment.

Nature’s super water purifiers to the rescue

To overcome the challenge of water scarcity and make the process of desalination more sustainable, water tech company Aquaporin has developed a biomimetic membrane based on the aquaporin water channel protein to boost standard polymeric membranes with a biological water channel. The company has taken this breakthrough technology to new heights in the EU-funded AMBROSIA project, which produced the world’s first biomimetic brackish water reverse osmosis (BWRO) membrane and developed it from lab to industrial scale. With its potential to disrupt the current RO technology, making it more cost-effective and energy- and water-efficient, AMBROSIA’s biomimetic membrane is an important contribution to the desalination industry. Project coordinator Jörg Vogel explains how the project scaled the membrane from small coupons, no more than a few square centimetres in size, to a full roll-to-roll production of several thousands of square metres: “Within 3 years of the AMBROSIA project, we achieved this task and developed industry-standard elements that can match or outperform commercially available products from suppliers with more than 30 years of manufacturing experience. This means that we now have a pre-commercial Aquaporin Inside® BWRO membrane available.”

Pioneering technology for drinking water and industrial applications

The journey from small pilot scale to coating hundreds of metres of membrane was not without challenges and required a collective effort from the whole company. “We had a lot of troubleshooting to do,” says Vogel, “especially to ensure that we could transfer the protocols from lab to machine and make a stable and consistent product. This involved the R&D group in Denmark, running more pilot trials with our team in Singapore as well as many tests on the full-scale machine itself. In the meantime, our protein and research specialists had to optimise our Aquaporin Inside® solution to fit the new requirements of large-scale production, while our business development and sales team worked hard to find potential customers and test partners that were willing to try something new.” The biomimetic membrane lays the groundwork for targeted product development in the desalination, and food and beverage industries, as well as in the development of low-energy BWRO filtration for industrial and municipal water. In fact, the membrane is already playing a key role in research and innovation projects in Europe and further afield. “It will feature in the context of the Horizon 2020 REWAISE project, where the membrane’s chemistry will be further optimised and tested in pilot industrial and near-commercial settings,” notes Vogel. “And we are also developing BWRO filtration for water and resource recovery in a European project focusing on municipal waste water.” The significant results achieved by AMBROSIA will ultimately contribute to global efforts to overcome water scarcity, one of the biggest challenges of our times.

Keywords

AMBROSIA, water, membrane, desalination, BWRO, energy, Aquaporin, biomimetic, climate change, reverse osmosis, brackish water