Innovations for Europe’s railways offer a glimpse of the future for passengers and freight

The complexity of the European rail network presents a range of challenges related to infrastructure, signalling and telecommunications, passenger experience and logistics. Key to revamping the network is a new generation of more reliable, comfortable, environmentally friendly trains, with reduced life-cycle costs. New rolling stock will also reduce track damage, making maintenance and repair costs substantially cheaper. Through a series of case studies, the EU-supported project RUN2Rail developed several technological concepts for the next generation of running gear (wheelsets, suspensions and bogies). As part of the Shift2Rail (S2R) Innovation Programme, RUN2Rail worked in close collaboration with a complementary project, PIVOT.

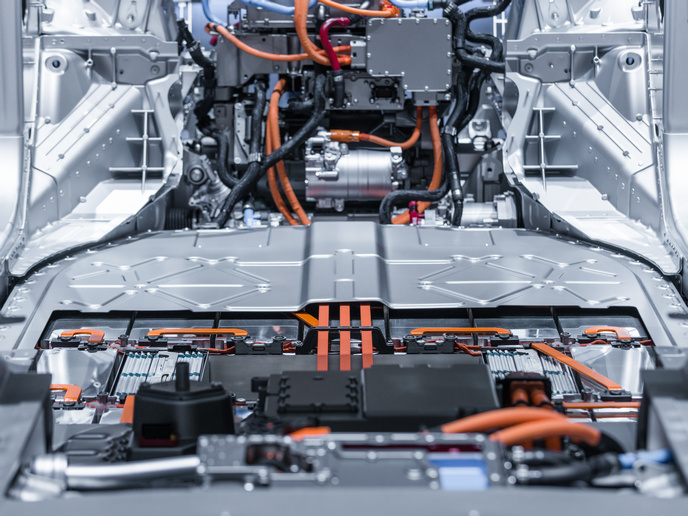

New concepts for future trains

RUN2Rail was divided into four investigative areas: advanced running gear condition monitoring, new materials and production techniques, mechatronic suspensions for railway vehicles, and prediction/reduction of interior noise. The team (15 partners from eight countries) used mathematical models and simulation tools to forecast the evolution of various train systems. One case study looked at the use of metal additive technology (3D metal printing) to manufacture components which can withstand service loads and hard-wearing working conditions. Using knowledge of the metallurgical properties of metallic powders, in combination with expertise in the use of high-power lasers, allowed the team to produce an innovative axlebox. This has the required mechanical properties, but is 30 % lighter and smaller. Another case study investigated the rumbling noise coming from the wheels – notoriously difficult to quell. The team created a tool to predict interior noise for a given configuration of the vehicle’s suspension and suggested different ways to cut noise. One suggestion is to use more flexible end mountings for some suspension components. Tests were performed on an entire Metro de Madrid train set. “But we couldn’t introduce innovations without complying with extremely high railway safety standards. It was almost more challenging to devise a certification strategy for a vehicle with mechatronic suspension, than to design the new suspension itself!” recalls Stefano Bruni, the project’s technical leader. RUN2Rail created a regulation and standardisation (R&S) workstream, with its own advisory group involving key industry bodies such as ERA and CEN. The project also provided input to the Shift2Rail Standardisation Rolling Development Plan by identifying relevant areas where impacts were likely.

All aboard!

In line with the priorities of the S2R initiative, RUN2Rail’s overarching goal was to make trains a more attractive option for passengers. The emphasis was not on increased speed, but rather on improved punctuality, reliability and comfort. Energy efficiency is also a draw. Another goal was increased profitability and competitive advantage for rail operators. This would benefit taxpayers, considering that European railways are often government-subsidised. “RUN2Rail was an opportunity to radically rethink concepts that have been well-established for a century or more! To progress, we will have to further quantify implications and set certification protocols. In the not-too-distant future I hope we will see some of our ideas being, literally, rolled out,” says Bruni. Towards this aim, the research continues with two new projects, NEXTGEAR and PIVOT2.

Keywords

RUN2Rail, railway, track, train, rolling stock, running gear, suspension, passenger, mechatronic, noise, 3D metal printing, safety, standards