Cobalt-free Li-ion battery technology for next-generation electric vehicles

Electric vehicles (EVs) have come a long way in recent years, but there are still several shortcomings associated with their batteries. Limited driving range, long charging time and high cost are among the most significant issues. As battery technology evolves, it is likely these issues will be addressed. The EU-funded COBRA project is set to shake up the world of EVs by developing a cobalt-free lithium-ion (Li-ion) battery technology for the next generation of electric cars. According to Jordi Jacas, COBRA project coordinator, the project aims to introduce advanced and sustainable components for enhanced safety and performance, both at the cell and battery pack levels. “Our goal is to develop a novel Li-ion battery technology that overcomes many of the current shortcomings of EV batteries,” explained Jacas, who is a senior researcher at the Catalonia Institute for Energy Research battery section.

Sustainability, safety and performance

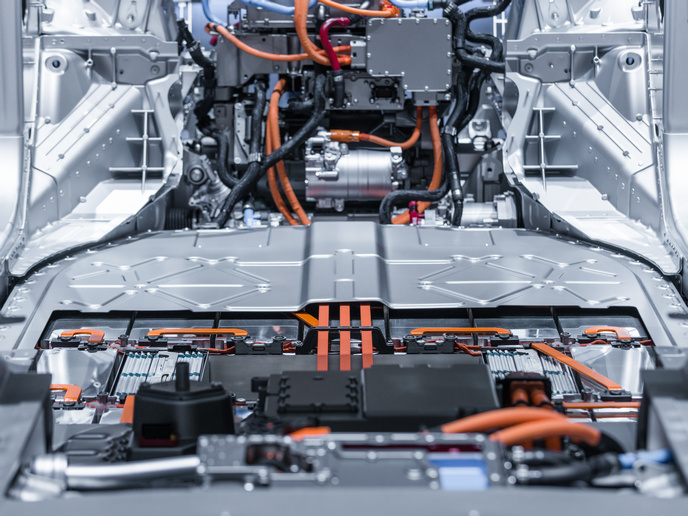

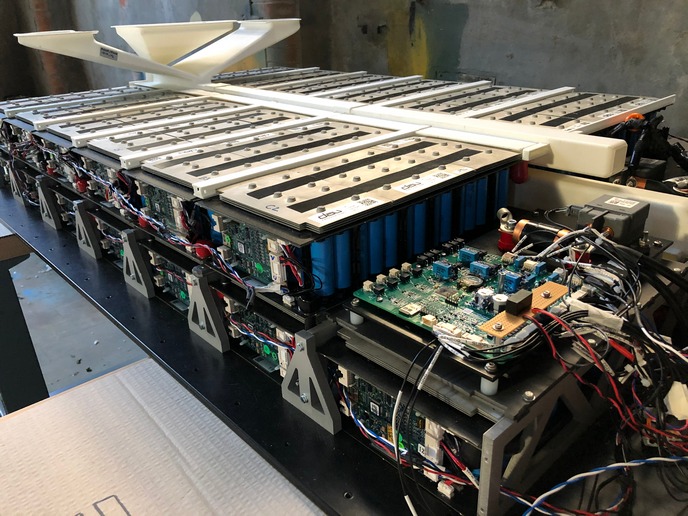

Cobalt, or Co, is an important ingredient in Li-ion battery cathode production. It accounts for a quarter of the cost of the battery. But since cobalt is scarce and prices are notoriously volatile, scientists are searching for ways to remove it from batteries. COBRA was born from a need to create sustainable Co-free materials with improved cathode performance and an advanced battery management system for better battery safety and performance. Combining these two characteristics led to the creation of COBRA, which worked towards the development of an innovative Co-free cathode technology with an increased capacity compared to current electrodes and operating at high voltages. The research team also looked at silicon-based composites obtained from waste stream recycling for long-life performance in the anode. Here the focus was on electrolyte stability and safety. That’s not all. COBRA also aimed to improve sustainability and performance while reducing costs at the cell level. The team conducted research at the battery pack level, which involved the integration of sensors, development of an advanced battery management system, and system testing and validation. Jacas emphasised that COBRA’s final goal is to deliver a demonstrator with a very specific cost target of no more than EUR 90 per kWh. “We have introduced life-cycle analysis studies at the early stages to ensure a minimal negative impact on the environment,” he said. “COBRA aims at improving all aspects of batteries, to create a competitive battery technology from a performance, cost, environmental and social perspective,” added Jacas.

From suppliers and manufacturers to end users and certification bodies

“Implementing a project demands the collaboration of a multi-stakeholder consortium with a multidisciplinary approach, with players across the value chain, from material suppliers and manufacturers to end-users and certification bodies,” he said. “The fact that all project partners are European will ensure that the knowledge, as well as commercialisation, remains in Europe.” This will help to overcome critical disconnects between stakeholders and ensures that project outcomes will be utilised commercially – and the project’s strategic importance for European competitiveness is evident. “The main project outcomes will be fast implementation to launch competitive next-generation Li-ion generation 3b mass production, enhanced Li-ion battery safety, increased cell-level energy densities and much more,” explained Jacas. The COBRA project offers a promising future for EVs by making them safer and more efficient, and reducing their environmental impact.

Keywords

COBRA, battery technology, Li-ion, cobalt, Li-ion battery, electric vehicles, EVs, energy, cathode performance