Faster fills and fewer spills for fruit and veg jars

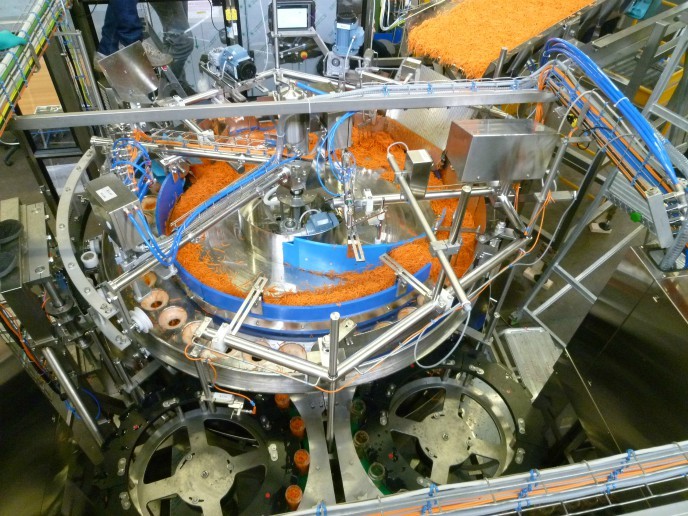

Fruit and vegetable processing companies make use of products of various sizes and shapes. This requires filling lines to be operated by people who also have to handle the products to fill the jars, raising issues of hygiene and product waste. Vibrations emitted by the vibrating plate on the filling machine also increase the potential for jars to break. At the same time, mismatched capacity between the handlers and filling lines results in a high rate of product changes. Food processing companies need a jar filling solution that will essentially upgrade the existing semi-automated filling lines and reduce direct human-product contact. The EU-funded project Mp-Filler is working to fill this need in collaboration with Italian company ZACMI, manufacturer of components and processing equipment for the food industry. Mp-Filler planned a feasibility study to explore optimal design with a view to facilitating customisation and integration into existing facilities. Other elements of the study included reassessing their intellectual property strategy and preparing a project execution plan for SME Instrument phase 2. One filler for all Ultimately, Mp-Filler is looking to deliver a prototype of a fully-automated rotating jar filling and tamping solution that can fill jars with most of the fruits and vegetables that processing companies typically work with. Project partners are targeting 50 % faster product filling and less than 2 % product loss from falls onto the floor. As noted on the CORDIS project web page, another goal is to realise operational cost savings of EUR 180 000 annually. “The project’s main goal is to have only one filler able to fill all types of fruit and vegetable products,” explains Giorgio Boselli, project coordinator and ZACMI managing director. “That means easy-to-fill products, products that need vibration to be filled, and products that need a final tamping section to press the products into the containers (mainly glass jars).” Boselli notes that there are many difficulties involved in arriving at such a solution. As such, “we have decided to produce a simplified filler called MPS-filler and test it with difficult-to-fill products like shredded carrots.” Trials carried out with this simplified filler over the course of the project provided important data to continue work towards the envisioned Mp-Filler solution. Year-round processing The project team aims to provide a final solution that will offer fruit and vegetable processing companies the possibility of utilising only one filler during the various seasons. This will be applicable to the widest possible range of fruits and vegetables, including peas, beans, green beans, corn, Jalapeños, pickles, cucumbers, cherries, and fruit cocktails and halved fruits. Dissemination activities include presence at expos, conventions and conferences. Project partners will also make use of different channels for communication plus advertising and web marketing, including a specialised website, social media and targeted web magazines. Although the project officially ended in 2018, work continues. “A reduced-scale prototype will be manufactured to test all speeds with various type of products,” Boselli reports. This will also enable testing of all other parameters required by the specific application before going on to build the final Mp-filler.

Keywords

Mp-Filler, fruit and vegetable, processing companies, jar filling, filling lines, tamping, product waste