More efficient design makes new generation electric ferries cheaper to run

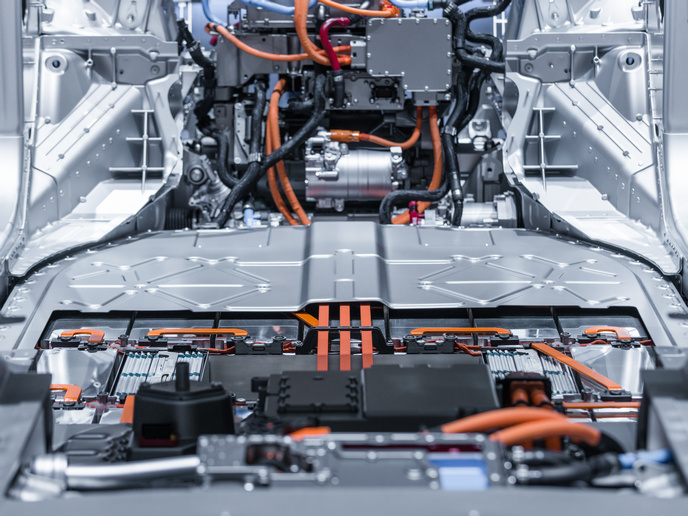

In many places across Europe ferries supply a service that is impossible to replace, so the hunt is on to transform the boats used from diesel consuming polluters to cleaner, more efficient transport options. Technological developments focus on the reduction of nitrogen oxides (NOx) and particulate matter (PM) – seriously hazardous to people’s health in urban areas – and energy efficiency measures. Methanol, gas and electrical propulsions are the replacements currently in place to achieve emission targets. The EU-supported GFF project has favoured the latter. It has developed a fully-electric, high-speed passenger craft, which will be the only zero emission ferry on the market that matches the performance of high-speed, diesel commuters. Their ferries can travel at 30 knots (55 km/h) and have extended autonomy (26 km routes in 30 min.). One thing that has been holding back the uptake of electric ferries is the recharging time, but GFF has managed to overcome this obstacle. “Fast recharge in port now takes less than 15 min,” says Mr Hans Thornell, GFF project manager. GFF is based on patented technology: the Air Supported Vessel (ASV) uses a pressurised air cushion which, running under the hull, reduces energy consumption by 40 %. “Our ferries can substitute existing diesel commuter ferries and can be used in sheltered waters, and inland, where conventional fast ferries are not permitted to go due to coastal erosion. Green Fast Ferries have a greatly reduced wake wash so we have huge market potential in inland waterways, archipelagos and urban waterways. It’s like a Tesla on water,” he says proudly. The 190 kWh LTO battery system was installed during the BB Green project, supported under FP7. BB Green is now an industry recognised brand. A 500-hour endurance test focused on cell voltage variation, and on efficient use of energy. The batteries performed extremely efficiently. “The battery pack has been used at between 5 % and 95 % state of charge and the 4 224 cells have had a voltage spread of 0,6 %, even though the cell balance function was deactivated almost half of the time,” explains Thornell. The GFF project has met its key objectives. “The first by having a Technical Ship Specification ready to be sent to any potential customer along with a price and a selected ship yard. The second objective has been met by dissemination of Green Fast Ferries' features through speeches at 25 conferences, references in 354 articles worldwide and a large number of real demo tours with potential customers. Today we are actively working on 12 commercial opportunities, two of which have resulted in concrete offers.” The project’s next step is a proof of concept. “Even if stakeholders have been on board the prototype on demo tours, almost no-one dares to be the first customer. We have to get the first new-built BB Green in operation as well as the charging infrastructure,” adds Thornell.

Keywords

GFF, Green Fast Ferry, electric ferries, emissions