The next generation of microbial fuel cells

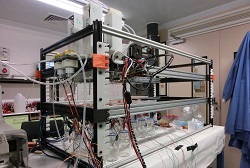

Bacteria placed in an anaerobic environment produce electrons that can be harnessed to produce electricity. Microbial fuel cells take advantage of the anaerobic respiration of bacteria to produce electricity, which is directly proportional to the rate of growth and metabolism of the microbes. Optimising bacterial communities with different feedstocks to become more efficient at electron transfer will ultimately improve microbial fuel cells. To achieve this, scientists of the EU-funded EVOBLISS project developed a robotic platform able to optimise liquid-based system using artificial evolution. “Our ultimate goal was to perform fundamental science that will help us understand bacterial evolution to both treat and use wastewater for energy generation,″ explains the scientific coordinator of the project Prof. Kasper Stoy. EVOBLISS was an interdisciplinary project involving state-of-the-art chemistry, imaging, microbiology and bio-energy. This was necessary for enhancing the understanding of living technologies and how to best design and exploit ground-breaking bio-hybrid systems. Robot-controlled and -evolved microbial fuel cells As a first step, researchers automated experiments through the development of a robotic platform (EvoBot) that uses artificial intelligence in the form of artificial evolution. The idea was to use robot-facilitated evolution to design functional ecosystems combining living organisms with artificial life chemistry that can increase energy production in microbial fuel cells. The robot platform was based on an open-source 3D printer converted to handle liquids and able to track output from experiments in real-time. Operation of EvoBot was possible through a standalone controller or remotely through a webpage. EvoBot ran complex optimisations using evolutionary algorithms and also had the capacity to intervene in experiments by adjusting various parameters such as the injection of nutrients and the removal of metabolic products. Scientists at the University of West of England (UWE), Bristol – one of the consortium partners – investigated various environmental conditions to achieve faster growth and maximum power transfer in microbial fuel cells. EvoBot successfully optimised the substrate concentration of the media in response to the microbial fuel cell power output profile. Using optical coherence tomography, an in situ imaging modality, researchers were able to monitor the inside of running microbial fuel cells for the first time. This provided unprecedented knowledge on the mechanical properties and organisation of living biofilm, the dominant form of microbial life on Earth and also the preferred microbial community inside the microbial fuel cells during energy production. In another part of the project, researchers at UWE investigated various materials for building microbial fuel cells. Dry clay comprised a promising and cost-effective alternative to currently used membranes, thereby expanding the potential applications of microbial fuel cells. Improved electricity output EvoBot was the first robot to enforce, monitor and interact with evolving systems such as living organisms used for specific tasks. EvoBot-nurtured microbial cultures demonstrated improved performance and evolved to generate sufficient energy to power another robot. Importantly, using EvoBot, scientists observed that feeding the UWE microbial fuel cell at the right time significantly accelerated the maturation of energy-producing cultures from four weeks to six days. The novelty of having a robot feed a microbial fuel cell was exploited by EVOBLISS partners in the successful start-up company Flow Robotics. Furthermore, EVOBLISS has successfully deployed microbial fuel cells in developing countries with significant help from the Gates Foundation. Prof. Stoy envisions “the application of the EVOBLISS toolbox of technologies to other relevant societal problems outside of energy production.″

Keywords

EVOBLISS, microbial fuel cell, EvoBot, robot, electricity, optical coherence tomography, 3D printer