Novel system removes debris from compressor

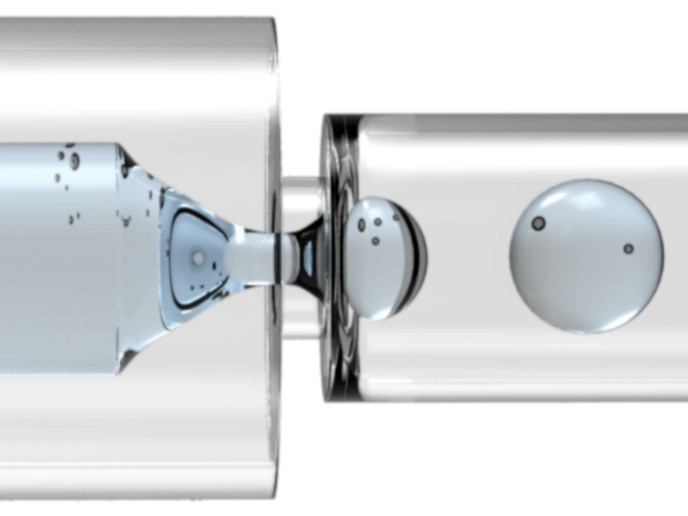

Modern aircraft are equipped with an ECS that provides air supply, thermal control and cabin pressurisation for the crew and passengers. However, it is one of the largest consumers of electrical energy since it uses bleed air. In such configurations, external air is bled from the fan or from the low/intermediate pressure stage of the compressor. For this reason, aircraft manufacturers are increasingly turning to electric ECS solutions that get fresh air directly from the atmosphere. In an electric ECS pack, the outside air is injected directly into the compressor via a scoop air inlet located on the aircraft's belly fairing. To protect the turbo-compressor and electrical pack from debris and consequently ensure reliable performance, it is necessary to filter the outside air. Within the ELECFILTER (Design of compressor air inlet protection for electrical ECS) project, scientists successfully developed a reliable protection system for the compressor air inlet. The solution is a multi-stage filtration system that includes a pre-filtering retractable flap, an inertial vortex separator, a coalescence filter and a medium filter. To successfully develop the system, researchers firstly performed a computational analysis of the air and particle flows around the scoop and inside the system. No-bleed electrical system architectures lead to increased efficiency gains in terms of reduced fuel burn. The newly developed filtration system is ensuring that the probability of losing of fresh air supply to the cabin stays within the set limits.

Keywords

Debris, compressor, aircraft, environmental control system, bleed air, air inlet