Improved safety for critical aircraft components

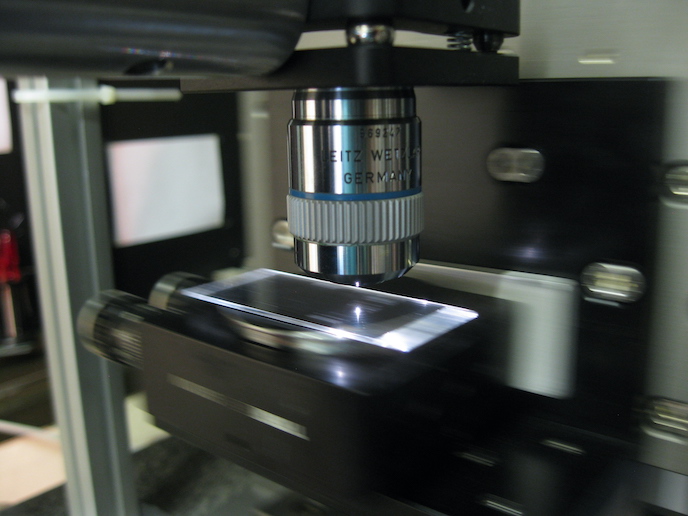

Titanium and its alloys exhibit high strength-to-weight ratios and excellent corrosion resistance. Given the additional benefit of withstanding extreme temperatures, titanium is particularly well suited to structurally significant item (SSI) applications in the aerospace sector. However, current NDT techniques to assess the titanium billets from which the components are formed are faced with several problems. They are expensive and complex, requiring prior knowledge of materials' properties and extremely precise probe positioning. As a result, the numerous small and medium-sized enterprises (SMEs) working in the field are facing difficulty competing with larger manufacturers. In addition, they have low sensitivity and repeatability, such that even large manufacturers have missed defects with catastrophic consequences. Funded by the EU, the QUALITI project developed NDT technology suitable for application during the manufacture of titanium components for the aerospace sector. The technology exploits a combination of two NDT methods. Phased-array ultrasonic testing (PAUT) probes detect defects within the volume of the billet, compiling information from a number of ultrasonic beams and employing beam steering to help correct for misalignments. The performance is equal to or better than industry-standard ultrasonic inspection. A restriction is that both systems are unable to evaluate the so-called ultrasonic dead zone, a region below the surface of the test object whose signals are confounded by strong interface echoes. In order to overcome this limitation, the QUALITI system employs eddy current (EC) inspection that relies on electromagnetism. A coil with alternating current placed near the surface generates a changing magnetic field producing EC in the vicinity. Changes in the EC properties provide information about defects. The automated EC technology is revolutionary in the field of NDT of titanium for SSIs in the aerospace sector. The combined QUALITI system now provides comprehensive defect detection in titanium billets that can be subject to surface defects during manufacture. It will have major impact on the safety and operating costs of airlines, on the profitability of titanium manufacturers and even on the expanded use of titanium now that reliable defect detection is possible.