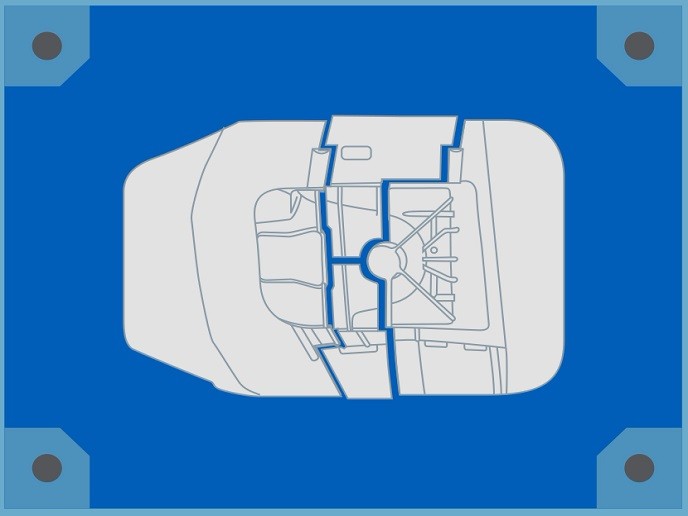

Using electricity to shape aluminium vehicle parts

More extensive use of lightweight materials in vehicles has been identified as an important means of achieving significant weight savings and subsequently, reducing fuel consumption and pollutant emissions. Materials like aluminium alloys are, however, less formable than mild steel, and significant amounts of springback after formation results in undesirable shape inconsistencies. The high workpiece velocities achieved during electromagnetic forming (EMF) can enhance the formability of aluminium alloys. Relying on the force generated by a magnetic field to produce the desired shapes in electrically conductive sheet metals, EMF has been established as a technically feasible and efficient means for either the expansion or the compression of cylinders (tubes). With the aim of drawing guidelines for the optimal selection of raw materials and EMF process parameters, researchers at DaimlerChrysler AG worked on identifying forming limits for aluminium alloys of interest. Moreover, relationships between characteristics of the electrical subsystem and deformation responses of the selected alloys were investigated. Initial tube geometry (diameter and wall thickness) and material formability were identified as the most important factors that would need to be taken into account for tube preforming. In addition to material properties, induced forces that depend directly on electric current pulses and influence the forming velocity have a significant role in the success of the preforming process. To avoid defects such as wrinkles due to excessive tangential stress or fracture caused by excessive pressure, manufacturers would need to select appropriate settings for the EMF equipment. More specifically, computer-aided trial and error techniques proved to be indispensable in establishing the appropriate settings that include the pressure profile and the axial feeding of material over time.