Application of TOFD methods to weld inspection

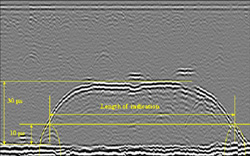

The project had seven goals, which included the performance of TOFD inspection and procedures for the application of TOFD. Training and certification needs were also addressed, as were the design of acceptance criteria. Technological, economic and human factors were also considered. The performance of TOFD was compared and contrasted with conventional NDT techniques. These were defined by the European standards applied to the testing of pressure vessels at the manufacturing stage. The results of each evaluation carried out on every specimen were stored in a database set up on a website. The TOFD results needed to be compared quickly and reliably with those obtained through NDT. Therefore, specific tools were developed to facilitate this process. Comparisons were normally performed through the use of Probability of Detection (POD) curves and tools for statistical analysis. At the same time, optimised TOFD procedures and specific related acceptance criteria were also developed. The TOFDPROOF project drew up training and certification guidelines which were then distributed to the relevant organisations. These included the NDT society, the European Committee for Standardisation, or CEN and those companies within the European Union which deal with weld inspection. The TOFD method was then applied on site to two welded components. This enabled the technical efficiency and financial competitiveness of TOFD compared with NDT, to be highlighted. The results were then to be disseminated among specialists in NDT.