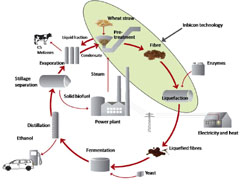

Refineries for bioethanol and power production

In the future IBUS will provide the main basis for refineries producing biofuels. The CO-PRODUCTION BIOFUELS project developed the system to produce bioethanol through the integrated conversion of conventional sugar and starch and straw or whole crop grain feedstocks. The by-products of this process comprise animal feed for cattle and fish and a solid biofuel low in alkali chlorides. The project integrated the production of biofuel with a combined heat and power plant (CHP). This enabled the exploitation of large amounts of low temperature thermal energy resulting from the production of electricity. It also allowed maximum generation of power from the solid biofuel by co-firing in the power plant's boiler. The benefits of the IBUS system are considerable, including the ability to produce bioethanol without the use of fossil fuels. Carbon dioxide (CO2) emissions are overall negative because the greenhouse gas is condensed following fermentation and the liquid CO2 used for enhanced oil recovery (EOR). The process was fully sustainable. It returned plant nutrients to the soil through animal feed and produced bioethanol without generating waste water or volatile organic compounds, such as dioxin. IBUS also used household waste in a very efficient manner. The recyclable material was first removed before the biodegradable fraction was converted to bioethanol.