Eliminating 'engine knock' for increased operating efficiency

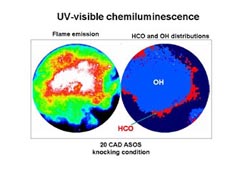

Control systems of modern automotive spark-ignition engines are designed to continually adjust the spark timing and angle, in order for power generation and fuel economy to be maximised. However, spontaneous combustion of the air and fuel mixture may occur ahead of the spark-initiated flame front, midway through the combustion cycle. Such abnormal combustion, more commonly known as engine knock, may cause extremely high pressure spikes that can destroy pistons and rings in the engine. The results of recently completed experiments and kinetic modelling simulations of the spark-ignition process offered new insights into how auto-ignition is initiated and influenced by engine and fuel parameters. The ultimate aim of MINKNOCK project's research efforts was to clarify which parameters are most important, so future work can be better directed toward possible mitigation of problems. Thermal, fluid mechanical and chemical mechanisms may even be found that they can be harnessed and controlled to provide rapid energy release and minimum risk of engine damage. For this purpose, advanced non-intrusive and quantitative imaging diagnostics techniques were employed at the laboratories of the Consiglio Nazionale delle Richerche on an optically accessible spark-ignition engine. To visualise inside a prototype Zetec-SE Sigma engine's head, transparent but resistant to thermal stress materials were chosen for the engine cylinder. The engine, equipped with a modern ported fuel injection (PFI) system, was lead by a flexible electronic control unit to ensure optimum combustion. Imaging and chemiluminescence analysis from ultraviolet (UV) to visual were simultaneously performed to examine the evolution of spray and flame with high temporal and spatial resolution. In the process, HCO and OH radicals proved to be suitable tools for evaluating the reactions occurring in the combustion chamber and furthermore, for identifying the auto-ignition start. Detected homogeneously distributed in the combustion chamber, their concentrations were ascertained to be dependent on the fuel properties and not influenced by the operating conditions. On this basis, detection of engine knock and controlling ignition timing to allow an engine to run at the knock threshold could provide for the optimum fuel consumption of spark-ignition engines.