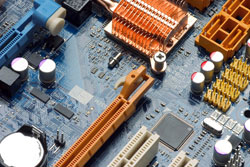

Aiming for lead-free soldering

The RoHS Directive for the restriction of the use of certain hazardous substances in electrical and electronic equipment bans the use of lead from solders and finishes. Motivated by this, the EFSOT project focused on a next generation environment-friendly soldering technology. For an easy transition to lead-free soldering technologies, current industrial processes need to adapt and possibly adopt new methodologies. To improve the competitiveness within the technology, the EFSOT project promoted reliable, efficient and sustainable lead-free soldering techniques. One of the key results was an innovative solder paste for lead free soldering that was further optimised for a robust performance and a reliable solder joint. It has been developed on the basis of SnAgCu alloys for fine pitch soldering. This innovation is suitable for numerous applications, ranging from the consumer to critical automotive electronics. The new solder paste displays excellent performance properties similar to the common SnPb solder paste. These include printability, wettability under air and reliability of the chemical behaviour of residues after reflow joints. The trademarked product is widely available not only in Europe, but also overseas. For further information click on the project site at: http://www.efsot-europe.info/servlet/is/1/