Robots lead the charge in recycling electronic waste

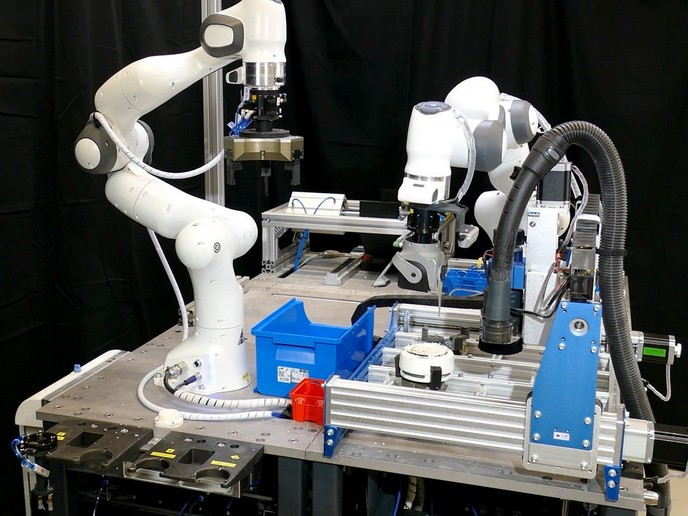

The growing challenge of electronic waste (e-waste) has created an urgent need for innovative recycling solutions. The EU-funded ReconCycle project has developed a cutting-edge robotic work cell that combines modular hardware, soft robotics and AI to streamline e-waste disassembly.

Revolutionising e-waste recycling

Recycling e-waste is notoriously complex due to the diverse states of damage and the variety of device models involved. “ReconCycle’s self-reconfiguration approach addresses these complexities by integrating modular hardware, AI-driven software and adaptive manipulation techniques,” explains project coordinator Aleš Ude. The system employs standardised modules that can be reconfigured for different device categories. Engineers initially guide this process, while AI autonomously adapts to variations within each category. “By leveraging advanced computer vision and vision-language models, the robotic work cell predicts optimal actions and ensures safe handling of fragile and rigid components,” highlights Ude. This self-reconfiguration capability makes the ReconCycle system particularly effective in addressing the challenges of recycling different models of the same device type. For example, electronic components such as heat-cost allocators require tailored disassembly processes due to their varying designs and conditions. ReconCycle’s flexible tools seamlessly adapt to these demands, minimising downtime and operational complexity.

Advancing robotics for recycling

The project made significant strides in modular hardware and soft robotics. Key innovations include the qb SoftHand 2 and the Variable Stiffness Gripper (VSG). “The qb SoftHand 2 features a redesigned three-tendon system for precise motions like pinch grasps and index pointing,” notes Ude. These tools enable efficient, non-destructive disassembly, which is critical for recovering valuable materials. Additionally, the VSG combines tactile sensing with adaptive stiffness control, ensuring secure handling of components without damaging them. Its modular design supports rapid tool changes, improving versatility. These advancements represent a significant step forward in soft robotics, opening new possibilities for automated recycling processes.

Enhancing efficiency through AI-driven action prediction

At the core of ReconCycle’s efficiency lies the innovative Action Predictor module. This module “enhances the adaptability of robotic disassembly by using large vision-language models (VLMs) combined with relationship graphs and a retrieval-augmented generation (RAG) approach,” notes Ude. It also predicts the next disassembly steps with high accuracy. By reducing the reliance on manual labour, the system lowers operational costs and improves worker safety. This is especially important in e-waste recycling, where hazardous materials pose significant risks.

Socio-economic and environmental impact

ReconCycle’s advancements contribute to a sustainable circular economy by increasing material recovery rates and reducing labour costs. The automated system boosts recycling efficiency and ensures safer workflows, as highly compliant robots can collaborate with humans to complete complex tasks. To date, 31 scientific papers have been published, highlighting the project’s contributions to advancing robotics and recycling technologies. Industry demonstrations, such as the Robothon competition and the introduction of the qb SoftHand 2 at ICRA 2022, demonstrate the project’s practical applications. These collaborations emphasise the importance of sustainability while fostering innovation in the robotics community. Beyond technical achievements, the project has significant socio-economic implications. By automating repetitive and dangerous tasks, ReconCycle creates safer working environments and reduces the reliance on outsourced labour in developing countries. This aligns with global efforts to make e-waste recycling sustainable and more ethical.

Driving future recycling technologies

The ReconCycle project marks a significant leap forward in recycling automation. By addressing the complexities of e-waste disassembly, its innovative solutions set the stage for more efficient, adaptable and environmentally friendly recycling systems.

Keywords

ReconCycle, e-waste recycling, soft robotics, robotic work cell, electronic waste, circular economy, recycling automation