A material used in the aerospace industry can fix bones

Bone fractures often require the surgical insertion of fixation implants such as nails or plates to hold the bone pieces together during recovery. Conventionally made of metal or composite materials, they are subject to wear. The resulting wear debris causes inflammation, osteolysis and loosening of implants. Additional corrective revision surgeries are often necessary with obvious socioeconomic consequences, highlighting the need for wear-resistant biocompatible materials in orthopaedic implants.

MP-1: an inert, tough, self-lubricating biomaterial

Scientists of the EU-funded MP-ORIF project addressed this shortcoming through a novel, biocompatible material that does not cause inflammation. “The biopolymer we invented, MP-1, originated from Aerospace applications and has many desirable features for orthopaedic use such as toughness, wear resistance and self-lubrication” emphasises project coordinator and CTO of MMA Tech Alisa Buchman. MP-1 belongs to the polyimide family of compounds. Thermally stable, it can withstand temperatures up to 700 ⁰C. It is also a pure polymer with no additives. Exhibiting fatigue and creep resistance at body temperature, it produces little debris compared to other polymers, metals, or ceramics. Even when debris is generated, it is larger than 2 microns and cannot be taken up by macrophages, minimising the risk of MP-1-associated inflammation. Easy to produce, MP-1 is friendly to the environment. It does not cause allergies like some metals while its low thermal conductivity means that people will not suffer when the weather changes. Importantly, it is biocompatible and does not require implant removal after healing has occurred, avoiding the need for revision surgery.

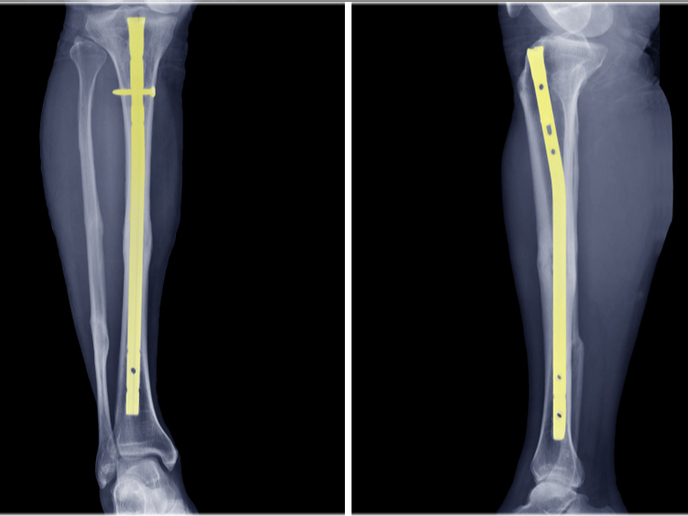

Orthopaedic implants based on MP-1

When first introduced, MP-1 obtained a CE mark in total hip implant surgeries as an acetabular liner implant replacing metal or ceramic materials. Using compression moulding, MP-ORIF partners successfully generated trauma implants such as nails, plates, screws and distal radius implants. These were tested in animal models with very promising performance results with cartilage and new bone formation indicative of fracture gap closing. The MP-1 material demonstrated excellent biocompatibility and short healing period. Orthopaedic trauma surgeries involve long cuts, which leave ugly scars on the healed limb. The MP-ORIF solution enables the surgeon to execute minimally invasive surgeries with shorter surgery time. Concomitant hospitalisation and recovery times are reduced, minimising healthcare costs and improving patient quality of life. According to Buchman: “MP-1 implants will be the game changing solution in trauma offering the opportunity for high-quality trauma surgeries to take place in small and medium hospitals as well as private clinics.” The next step is to perform clinical trials in humans in Europe and gain the CE mark, which will allow the distribution of the new implants in the worldwide market. The company M.M.A. Tech Ltd is currently extending the applications of MP-1 material for total knee implant replacing polyethylene as well as dental structures and implants replacing titanium.

Keywords

MP-ORIF, implant, MP-1, material, bone, fracture, inflammation, biopolymer, wear debris