Making use of the unique properties of cellulose-based nanomaterials

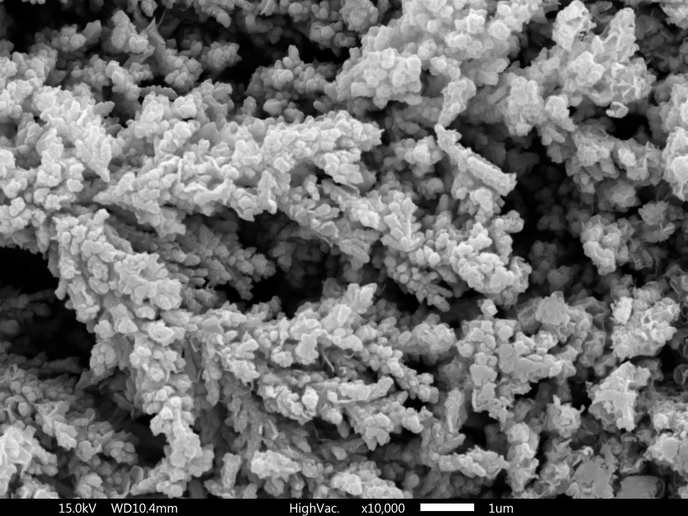

Thanks to their abundance, sustainability and superior mechanical properties, cellulose nanomaterials are becoming popular in various applications. For example, cellulose nanofibrils (CNFs) are used in coatings, lightweight packaging and the automotive industry. These cellulose-based materials that have at least one dimension in nanoscale (1–100 nm) are produced from wood, cotton and other lignocellulosic biomass through methods that involve disintegrating fibres by chemical and/or mechanical means. However, the manufacturing of CNFs could raise issues, such as how to produce material of even quality from batch to batch. The EU-funded NanoTextSurf project addresses such challenges by focusing on further developing the processes and technologies for production of cellulose nanomaterials. As noted in an Open Access Government news item, “the NanoTextSurf project aims at creating unique material properties and next-generation value-added products by surface treating materials with viscous pastes containing nanocelluloses.” According to the same news item, the viscous gel is formed when microfibrils constituting the fibre cell are separated from each other in the course of various processes. “In NanoTextSurf, the special characteristics of nanomaterials are used to stabilise pastes for thin coatings or to directly provide special properties like antifouling performance, improved strength or durability in friction and abrasive material applications.”

Pilot trials

A video highlights the kind of novel products containing nanocellulose and explains how these nanomaterials are applied to surfaces. Project partners have already run several pilot trials for all applications and have made significant progress in all four different application areas: membranes, protective textiles, friction pads, and abrasive materials. According to the news item, project coordinator VTT Technical Research Centre of Finland “has upgraded its surface treatment pilot facilities based on the targets of the novel applications and challenges seen during the project work.” It adds: “The pilot facility offers possibilities to perform trials at low speed for special applications with small material demands. Longer runs with continuous feeding with special pumps are also possible for scaling-up at high speed for producing enough material for testing end-product performance.” The news item also states: “The unique combination of nanocellulose, film processing technology, surface chemistry and the already established pilot-scale production facilities represent the new front of biobased and nanoenhanced materials for packaging, water and liquid purification, textiles and nonwovens and other high-value applications.” The NanoTextSurf (Nanotextured surfaces for membranes, protective textiles, friction pads and abrasive materials) project will end in October 2020. According to the project fact sheet on CORDIS, in addition to liquid purification, functional textiles for fire-retardant fabrics and linings, friction materials for transport and abrasive materials, other applications could also be considered for the deployment of nanotextured products. These include industrial wipes, hospital textiles, food packaging materials and air purification filters. For more information, please see: NanoTextSurf project website

Keywords

NanoTextSurf, nanocellulose, cellulose nanofibrils, nanomaterials, nanotextured surfaces