How to create a roadmap for occupational safety of nanomaterials

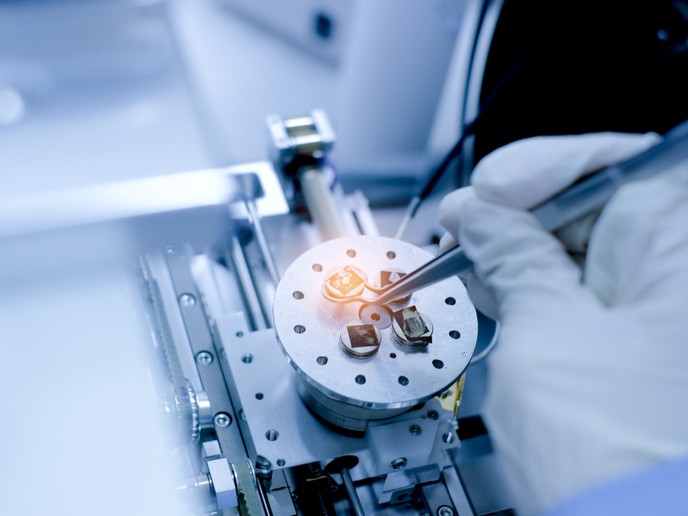

Nanotechnology is often regarded as a key element revolutionising several fields, including medicine, transportation, energy, food safety, security, ICT and environmental science, among many others. Broadly defined as science, engineering and technology conducted at the nanoscale, nanotechnology is developing rapidly. Scientists and engineers are increasingly focusing on making nanomaterials to take advantage of enhanced properties such as higher strength, lighter weight, increased electrical conductivity and chemical reactivity that their larger-scale equivalents lack. A growing variety of these ENMs is used in a wide range of products, including cosmetics, paints, sportswear, mobile phones, computer chips and batteries. However, many of the same properties for which nanomaterials are engineered and exploited, such as particle size, surface area and surface reactivity, also influence their inherent hazard and potentially threaten the health of workers, communities and the environment. Consequently, it’s crucial to assess the risks involved with nanomaterials. The EU-funded NanoStreeM project has made great strides in addressing this challenge. In a news item on ‘Open Access Government’, Dr Dimiter Prodanov from project coordinator imec, summarises the results of NanoStreeM. As noted in the piece, “there are more than 200 chemical compounds consisting of elements, such as silicon, germanium, copper, gold, hafnium, indium and many others, which are present in most computer and mobile phone chips.” Dr Prodanov also highlights some examples of ENM applications like “solar cell industry and energy storage, where a number of diverse materials based on rare elements are used. Every one of these applications requires unique expert insight into possible consumer, occupational or environmental hazards.” He adds: “The NanoStreeM consortium has taken up the challenge in defining a road map of occupational safety of nanomaterials in nanoelectronics where we have identified the existing gaps in our knowledge and formulated a number of recommendations for their mitigation.” The NanoStreeM project was set up “to promote good practices by identifying and implementing standards,” as explained on the project website. Another goal was to unravel the gaps in methodologies involving the governance of occupational risk in the semiconductor industry where nanomaterials are used.

Key project results

A major project outcome was the preparation of nanosafety training packages, with courses “focusing on semiconductor industry processes and the cleanroom environment,” according to Dr Prodanov. “The NanoStreeM project demonstrated that the nanoparticle emissions in normal operation mode of cleanroom processing tools are not likely to occur. Therefore, future studies in the semiconductor industry should focus on the assessment of the environmental impact, product end-of-life, and recovery of valuable elements through recycling.” The project also looked at the data gaps within the semiconductor industry, such as the lack of reliable data on nanoform toxicity and the risk assessment methods for nanomaterials. Dr Prodanov emphasises that “innovation guided by the Safe By Design principle must be aided by ongoing and future regulatory research.” He says: “Safe by Design includes three components: safe design, safe production, and safe use.” Dr Prodanov adds: “Finally, it is important to identify appropriate sources of information and communication channels for all actors along the supply chain, including the general public.” The NanoStreeM (NANOmaterials: STRategies for Safety Assessments in advanced Integrated Circuits Manufacturing) project ran between 2016 and 2018. For more information, please see: NanoStreeM project website

Countries

Belgium